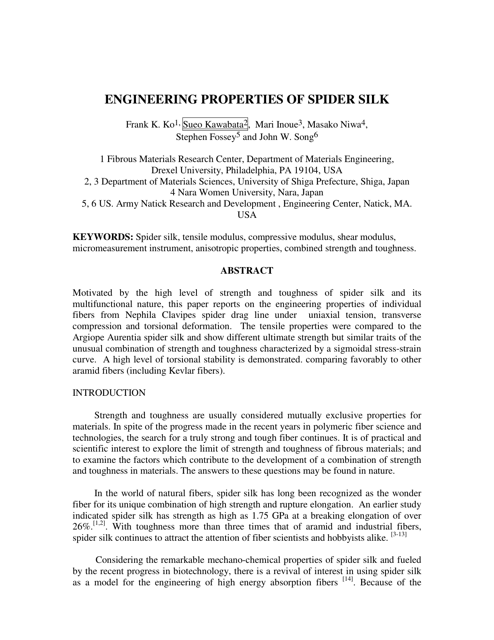

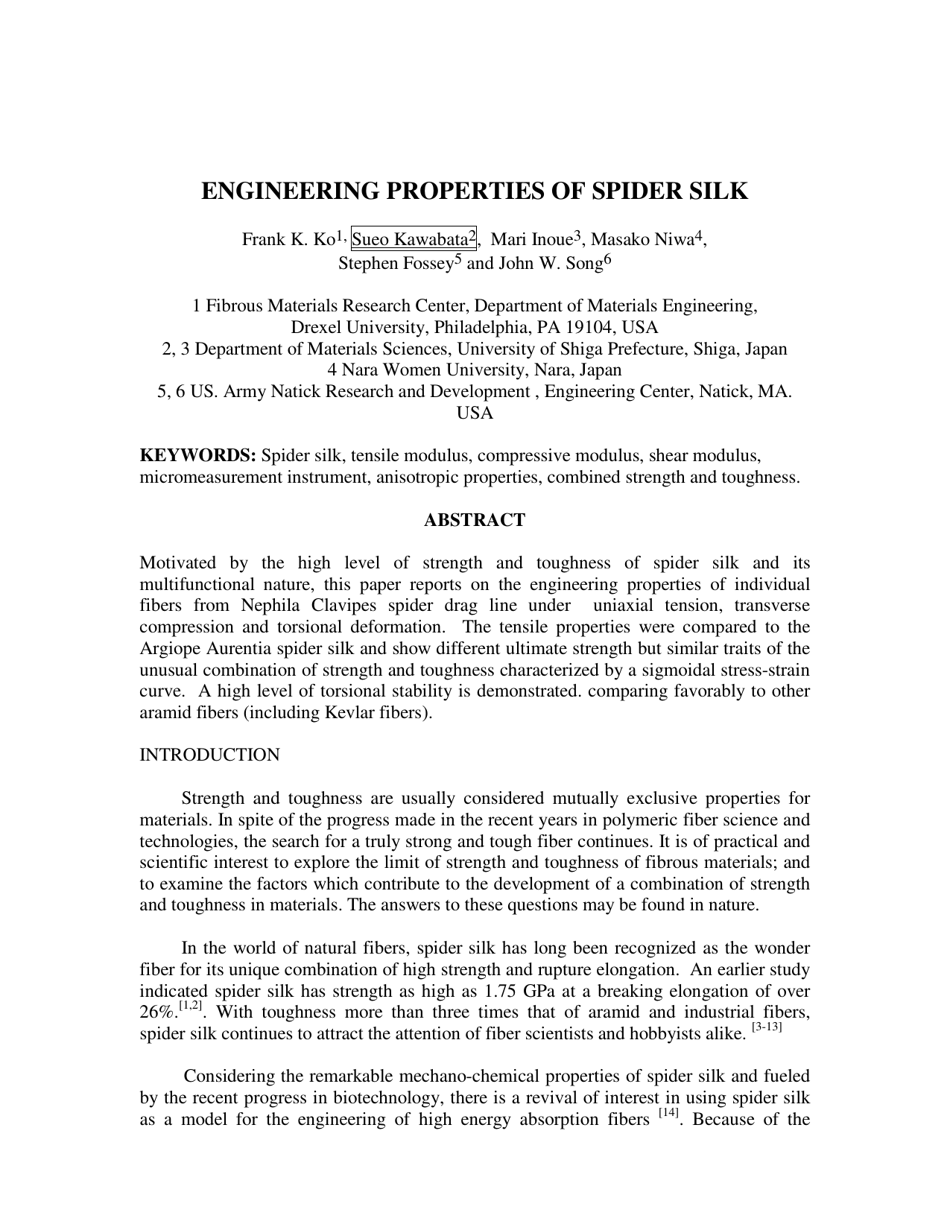

Engineering Properties of Spider Silk - Frank K. Ko, Sueo Kawabata, Mari Inoue, Masako Niwa, Stephen Fossey and John W. Song

The document "Engineering Properties of Spider Silk" by Frank K. Ko, Sueo Kawabata, Mari Inoue, Masako Niwa, Stephen Fossey, and John W. Song discusses the unique properties of spider silk from an engineering perspective. Spider silk is an extraordinary material known for its strength, flexibility, and toughness. This document likely focuses on exploring the physical and mechanical characteristics of spider silk and its potential applications in various engineering fields such as material science, biomimetics, textiles, and biomedical engineering.

The engineering properties of spider silk are filed by a group of researchers including Frank K. Ko, Sueo Kawabata, Mari Inoue, Masako Niwa, Stephen Fossey, and John W. Song.

FAQ

Q: What are the engineering properties of spider silk?

A: Spider silk has several remarkable engineering properties, including high strength, elasticity, toughness, and biodegradability.

Q: How strong is spider silk?

A: Spider silk is considered one of the strongest natural fibers. It has a tensile strength comparable to that of steel.

Q: What makes spider silk elastic?

A: Spider silk exhibits exceptional elasticity due to its protein structure, which allows it to stretch and absorb energy without breaking.

Q: What is the toughness of spider silk?

A: Spider silk is known for its high toughness, which combines strength and elasticity. It can withstand significant impacts and absorb energy without failure.

Q: Is spider silk biodegradable?

A: Yes, spider silk is biodegradable. It can be broken down by natural processes, making it an environmentally friendly material.

Q: Are there different types of spider silk?

A: Yes, different species of spiders produce different types of silk with varying properties. Some spiders produce multiple types of silk for different purposes, such as capturing prey or building webs.

Q: Can spider silk be used in engineering applications?

A: Yes, spider silk has generated interest in various engineering applications, such as biomedical materials, textiles, and protective coatings. Researchers are exploring its potential for use in areas such as bulletproof vests, artificial tendons, and lightweight composites.