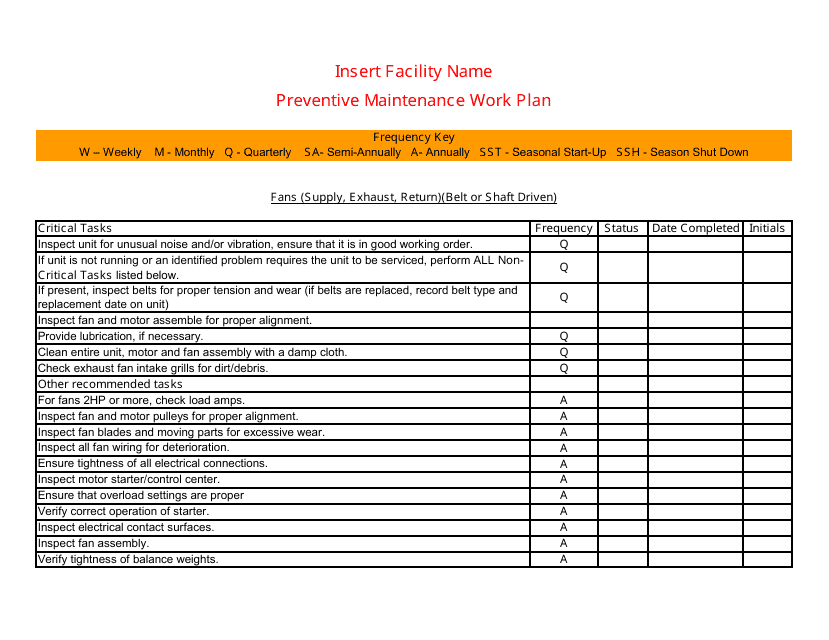

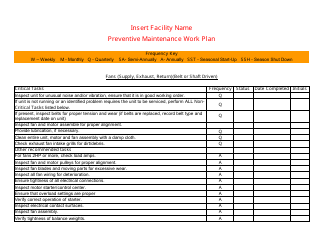

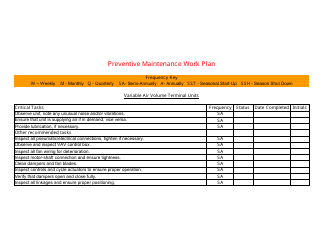

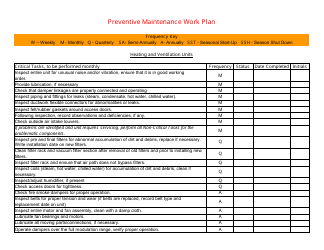

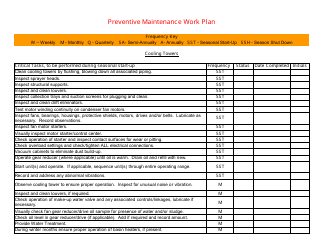

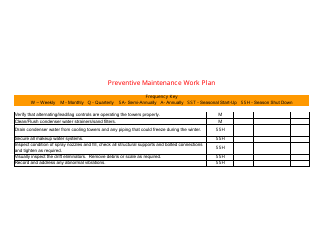

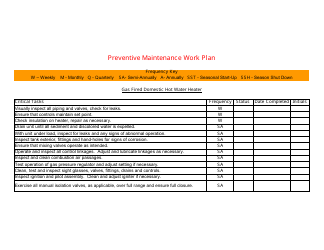

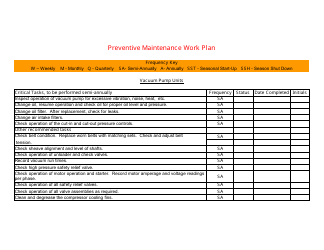

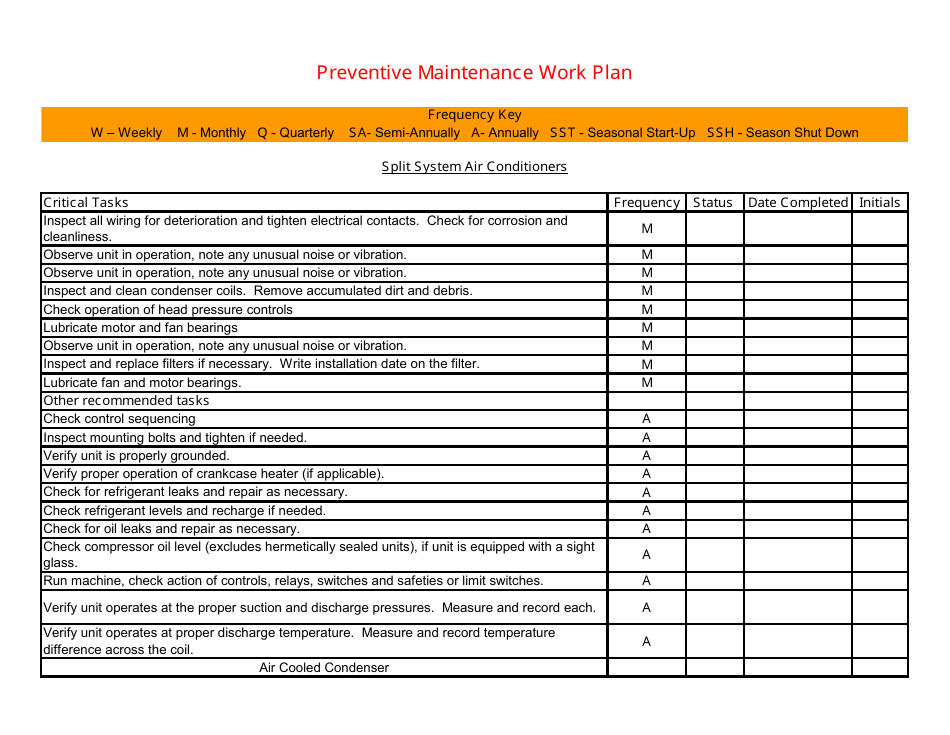

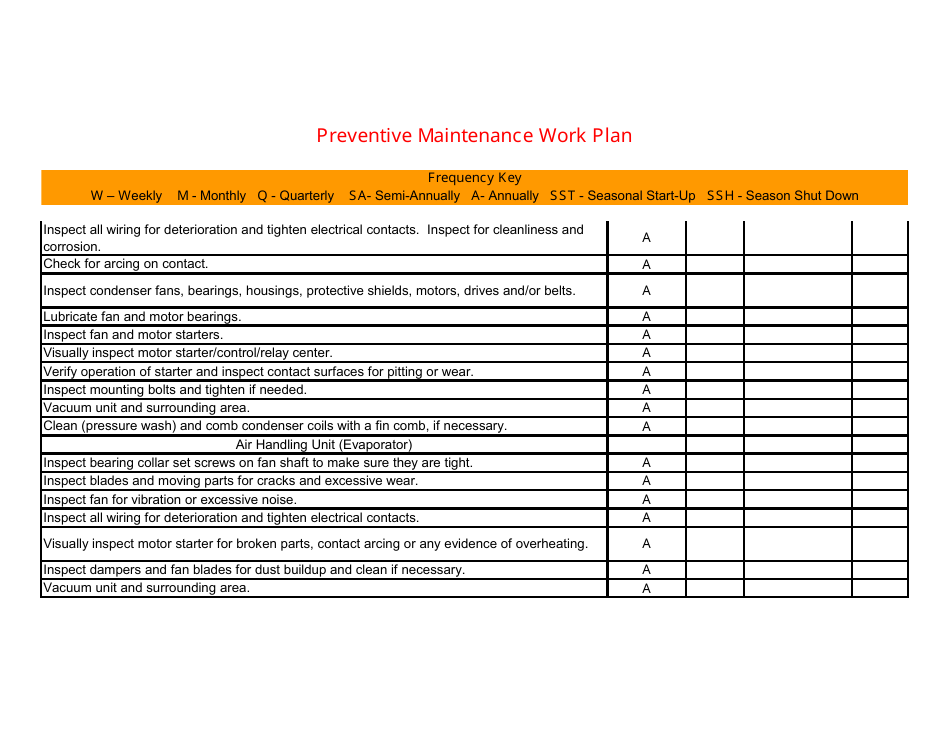

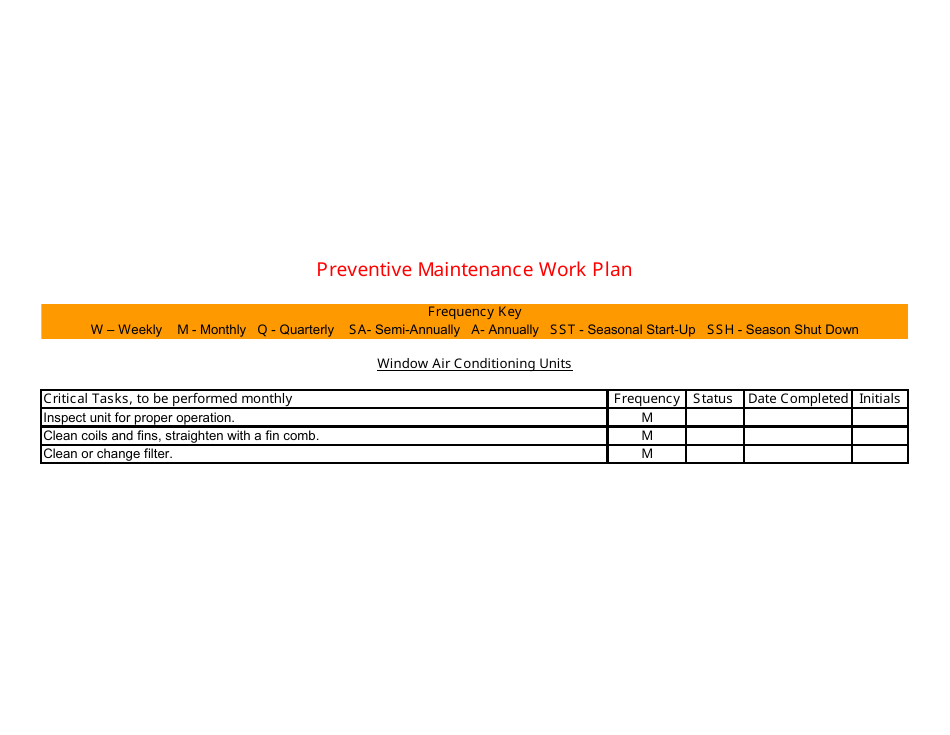

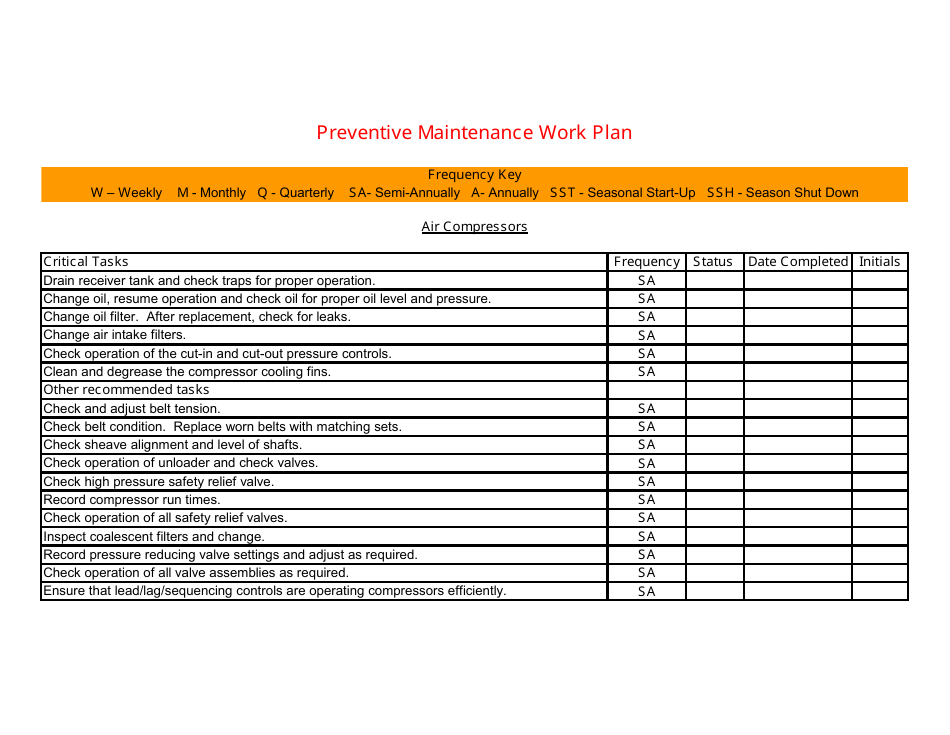

Preventive Maintenance Work Plan Template

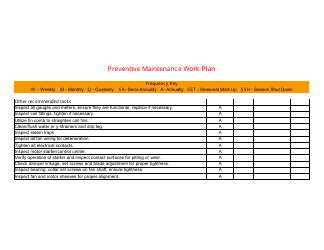

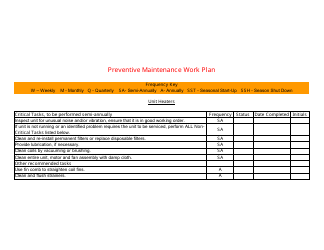

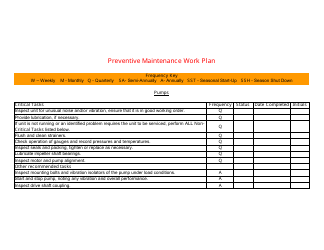

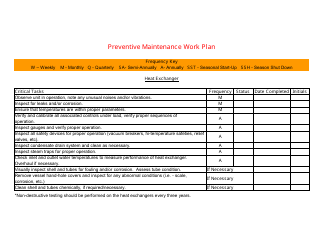

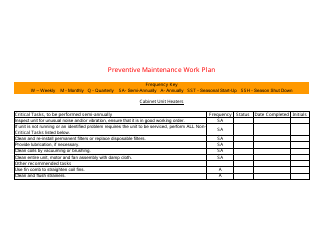

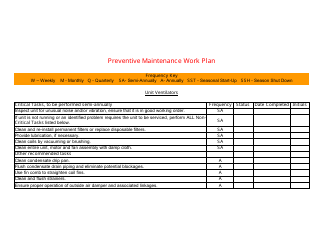

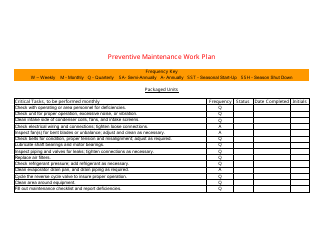

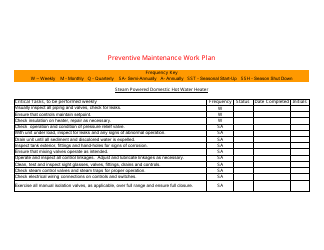

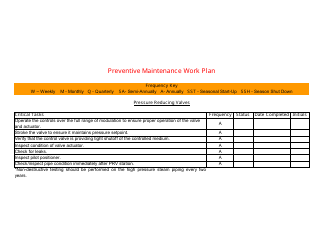

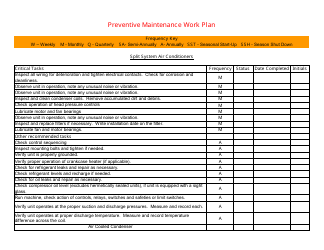

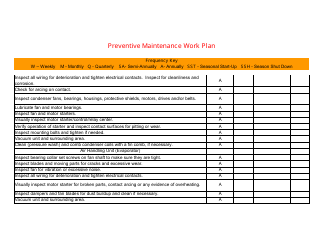

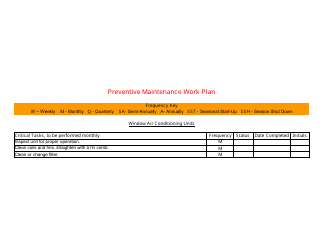

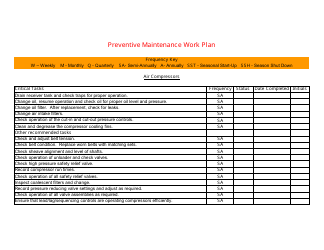

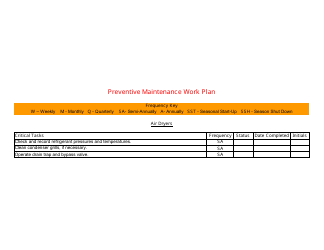

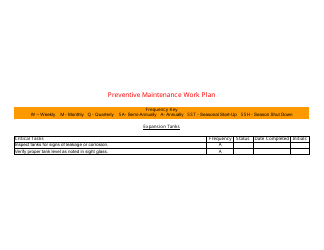

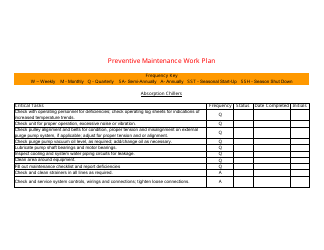

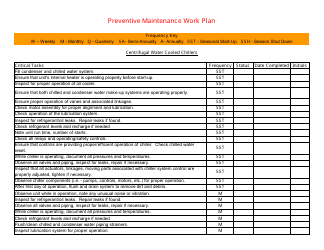

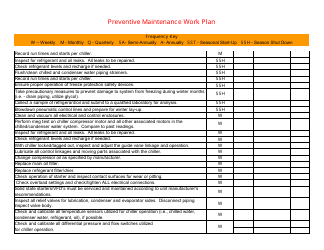

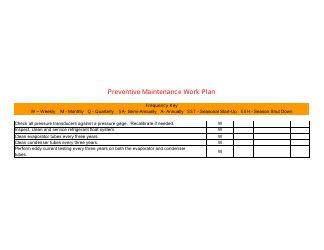

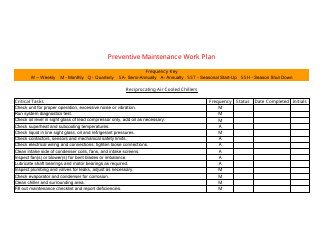

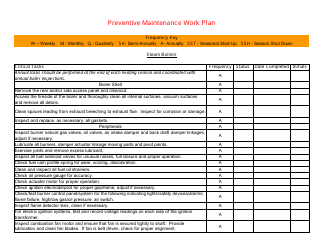

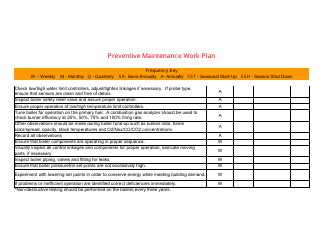

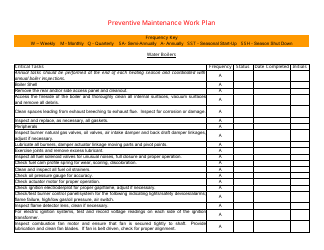

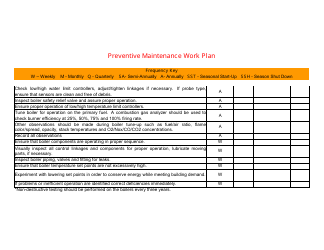

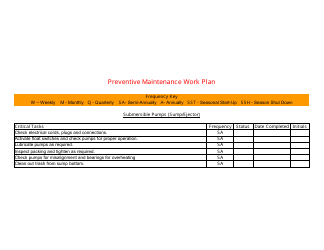

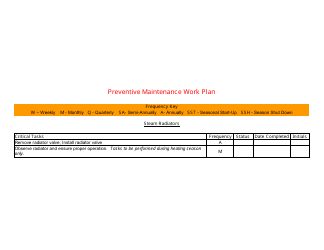

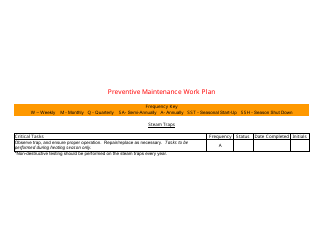

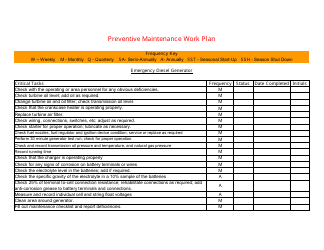

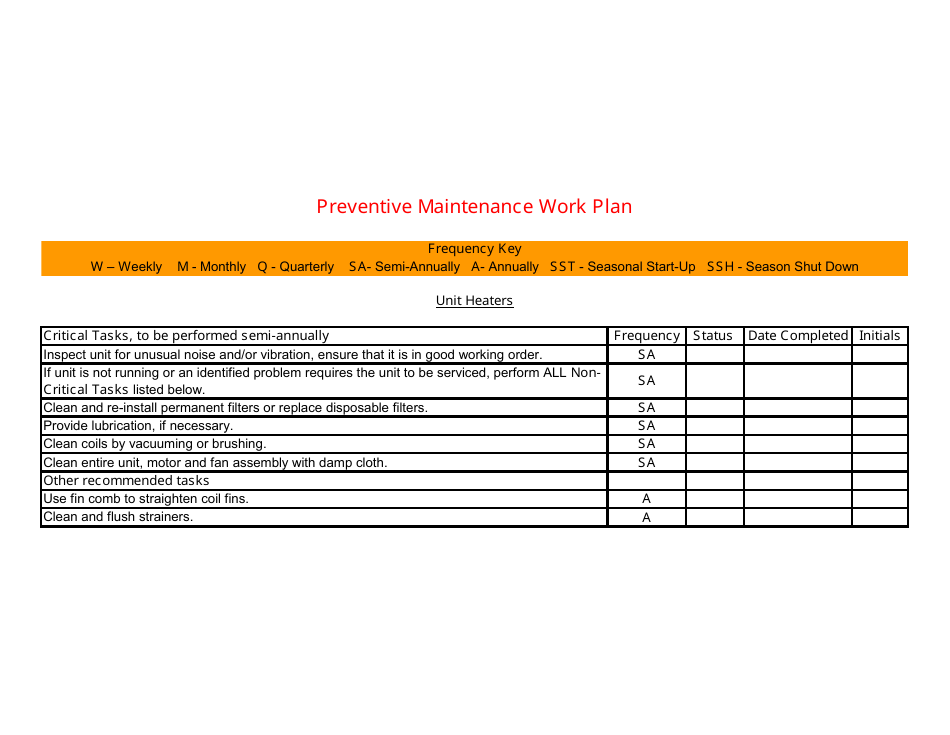

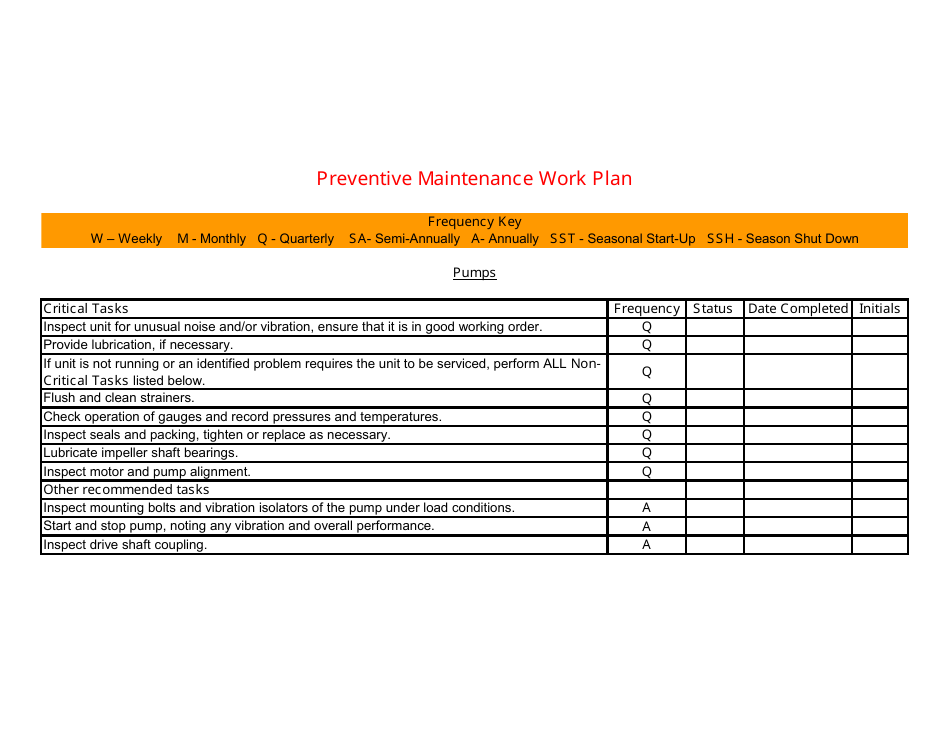

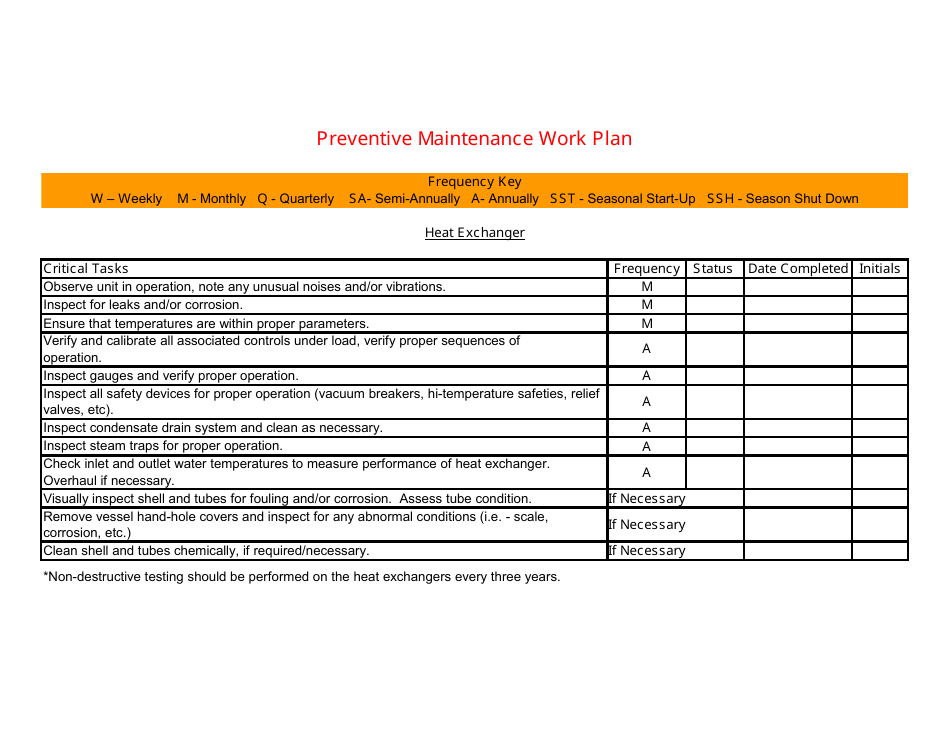

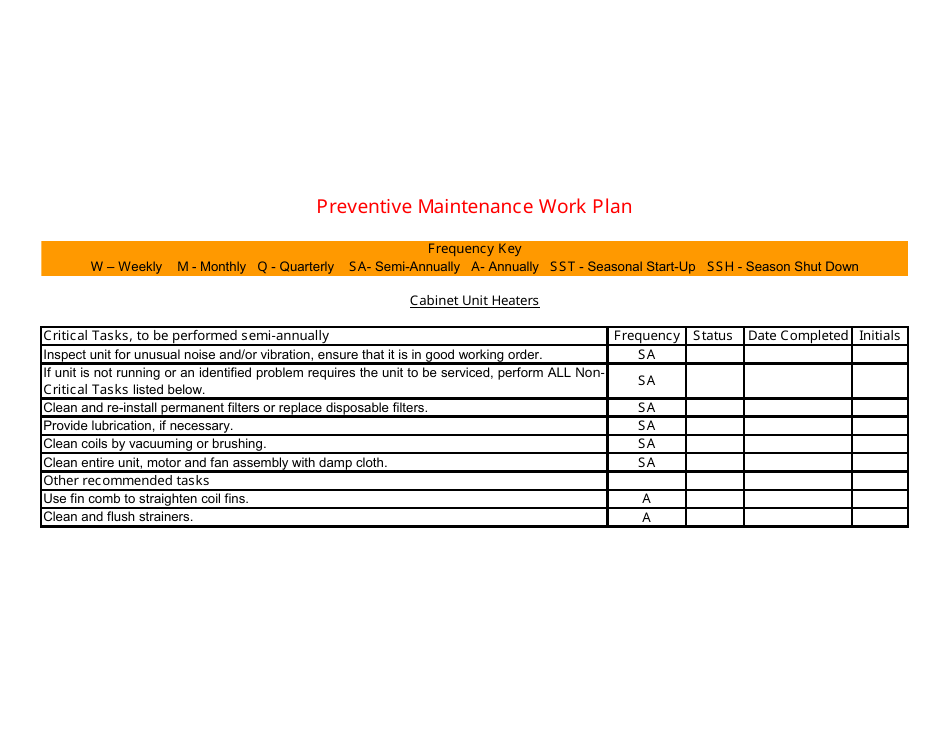

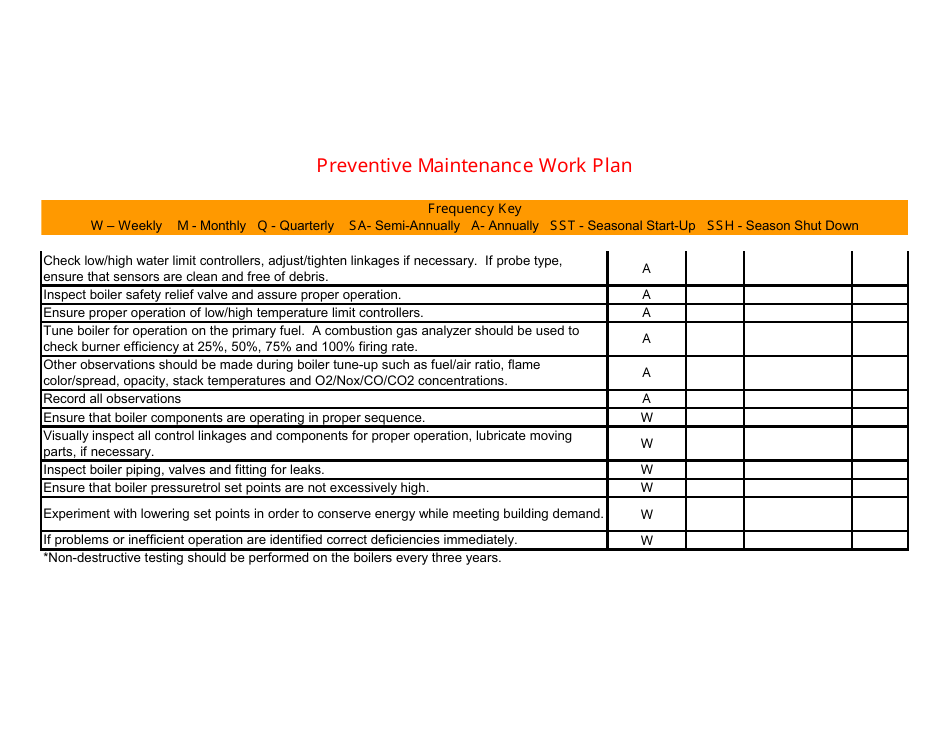

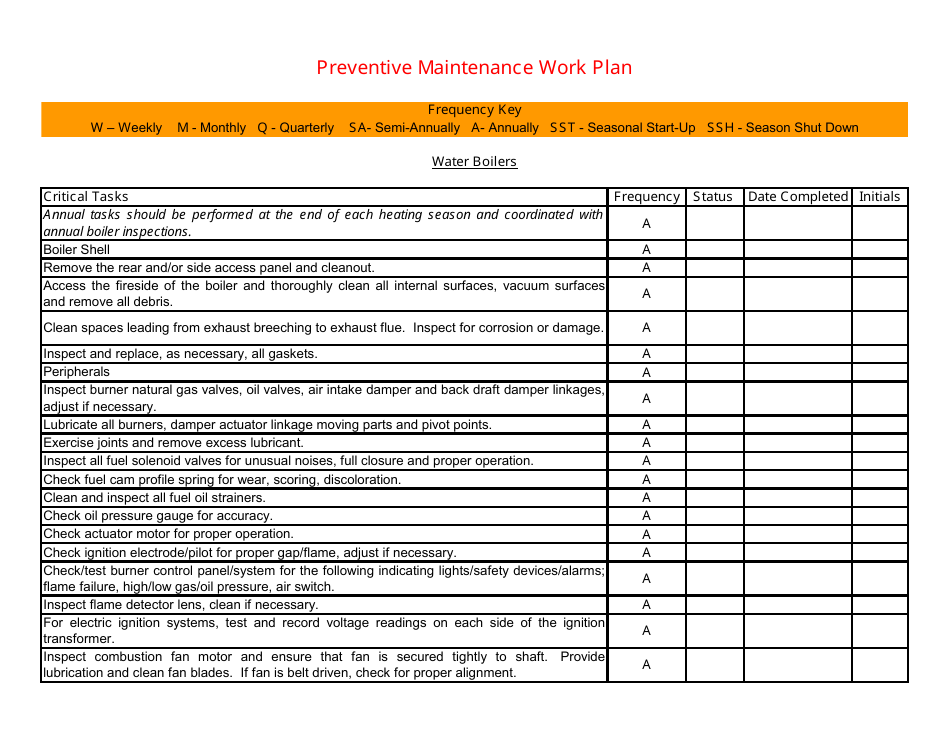

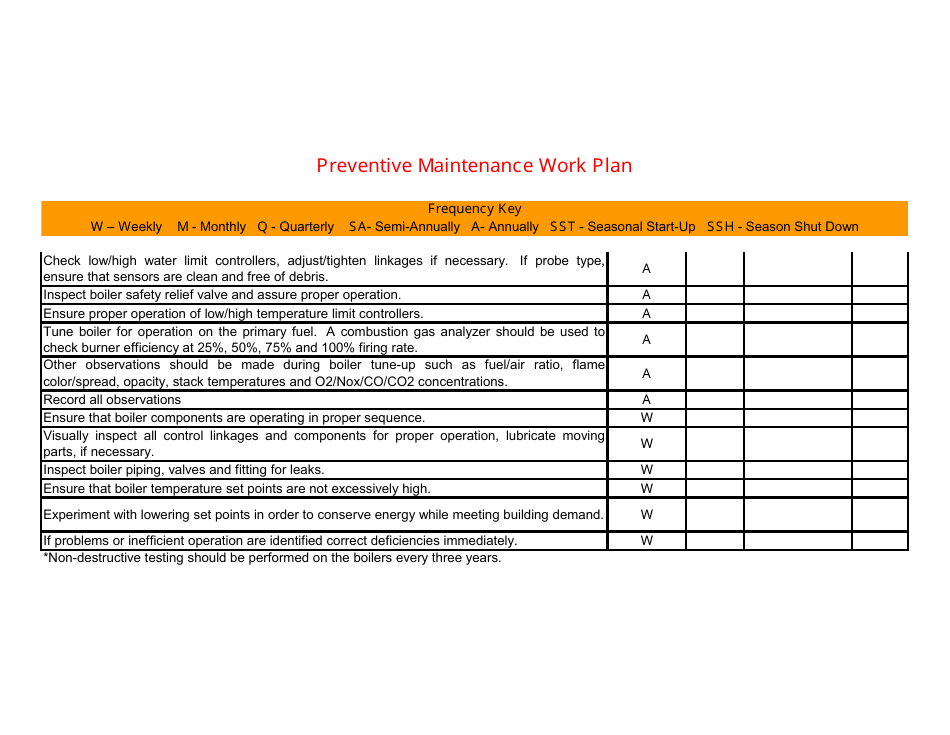

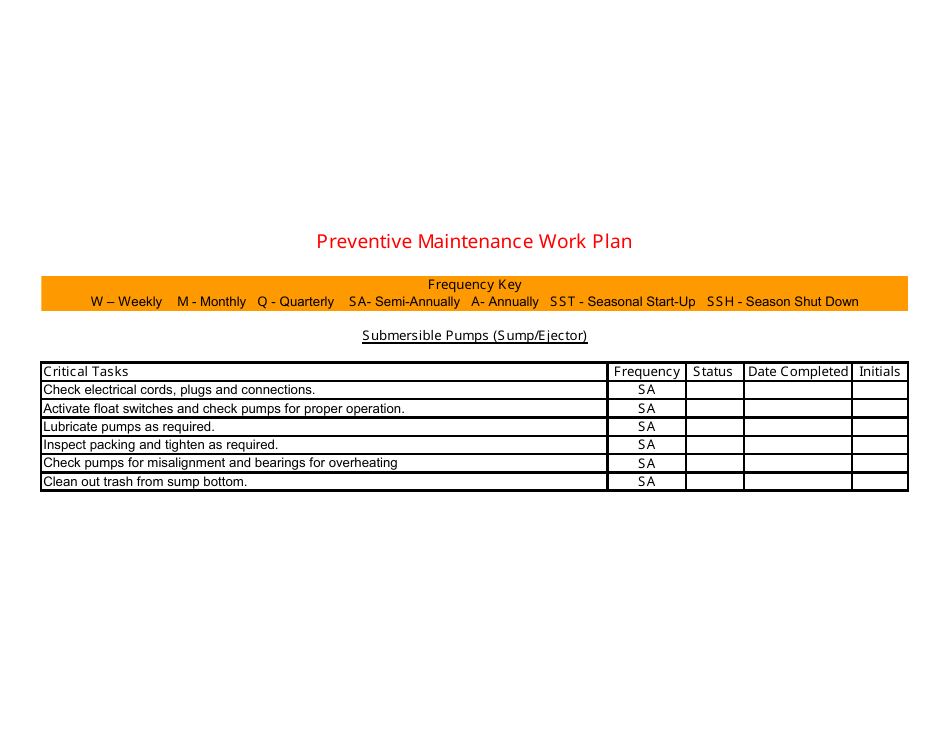

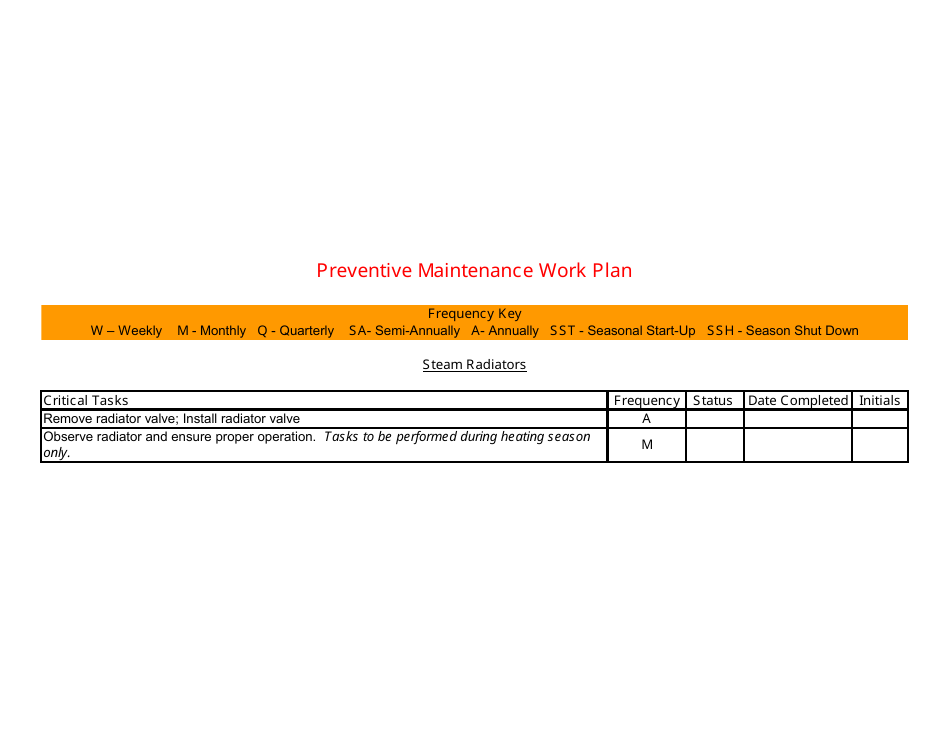

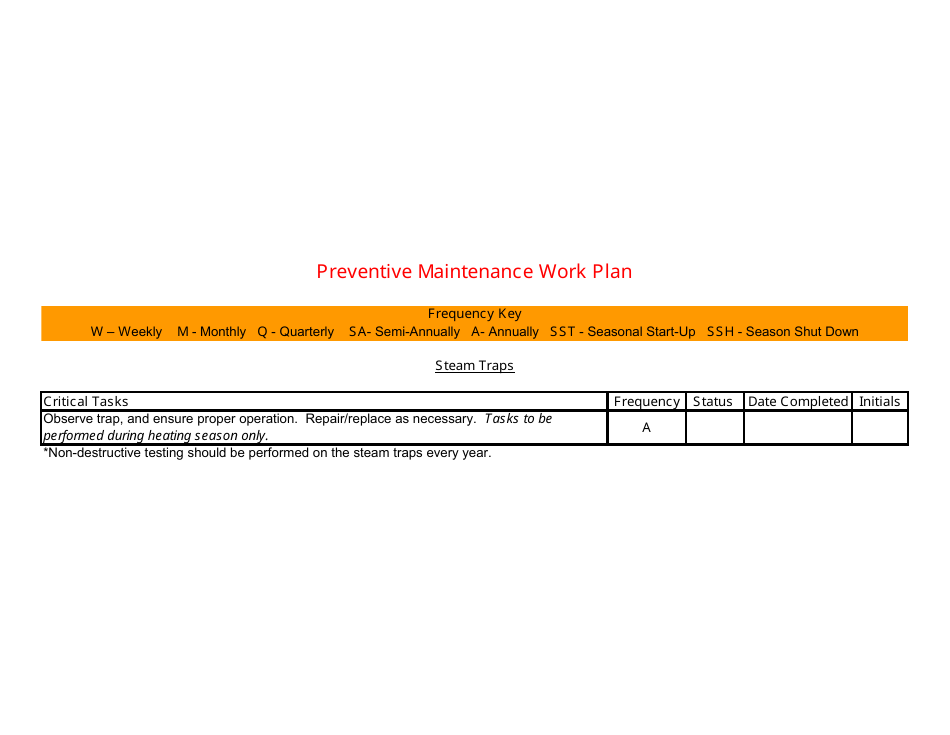

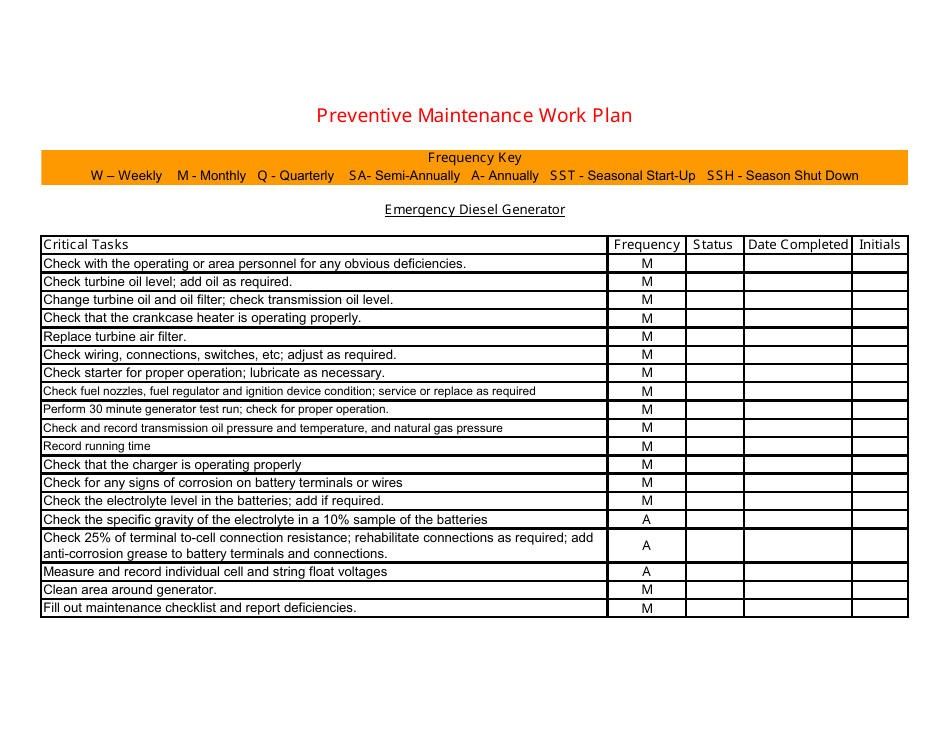

A Preventive Maintenance Work Plan Template is used for organizing and scheduling regular maintenance tasks to prevent equipment or facility failures. It helps ensure that maintenance activities are conducted systematically to keep assets in good working condition and reduce the likelihood of unexpected breakdowns.

The preventive maintenance work plan template can be filed by the facility or maintenance manager.

FAQ

Q: What is a preventive maintenance work plan?

A: A preventive maintenance work plan is a schedule or plan that outlines the regular maintenance activities needed to keep equipment and facilities in good working condition.

Q: Why is a preventive maintenance work plan important?

A: A preventive maintenance work plan is important because it helps ensure that equipment and facilities are regularly inspected and serviced to prevent breakdowns and ensure optimal functionality.

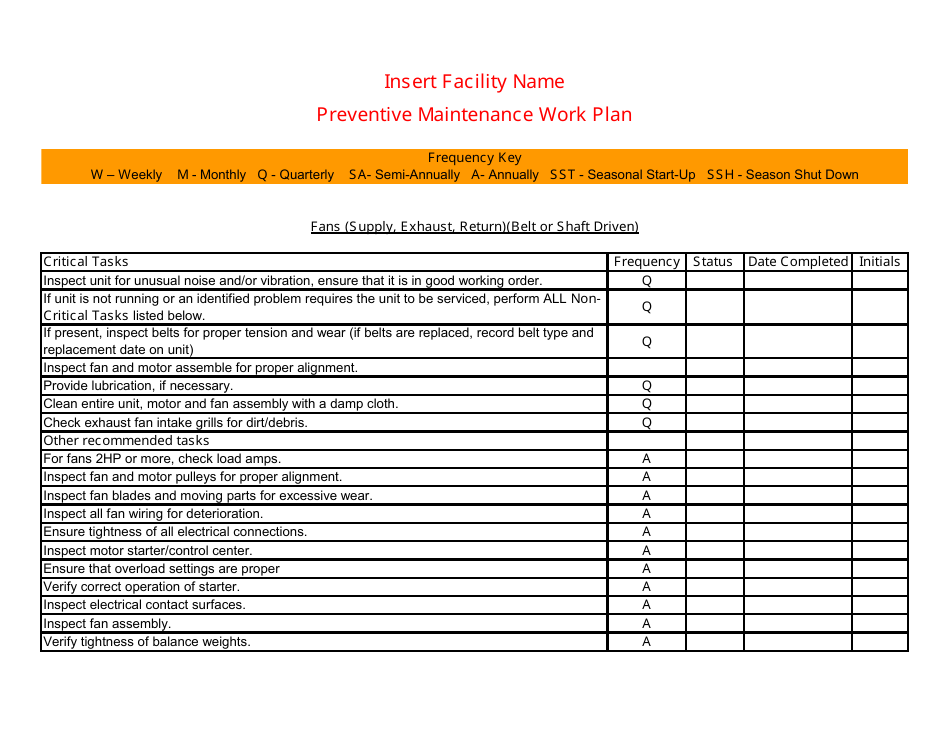

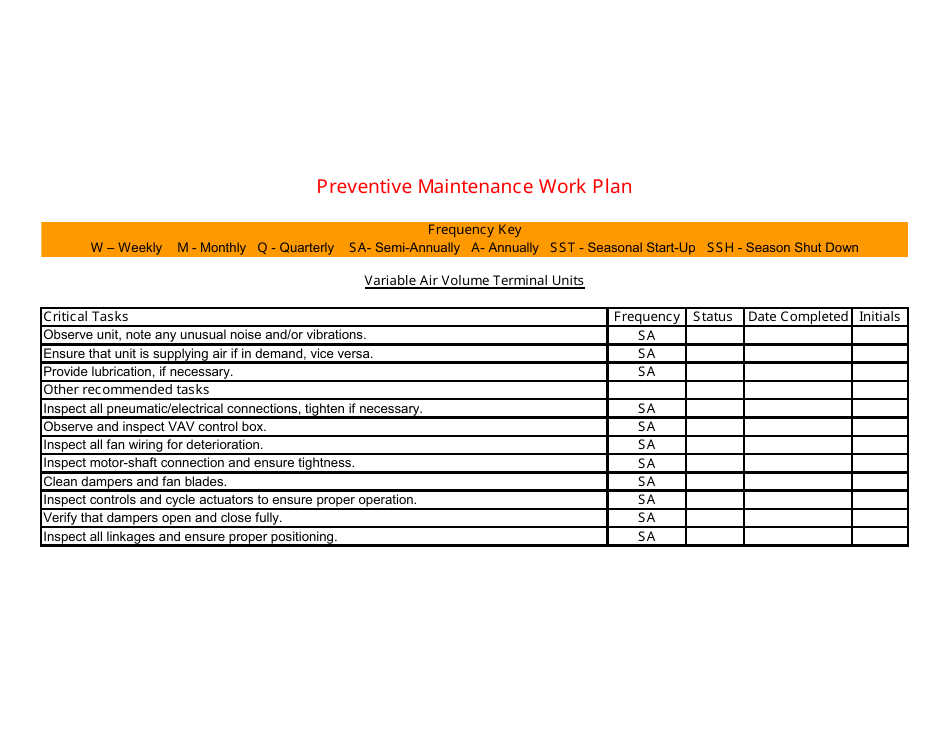

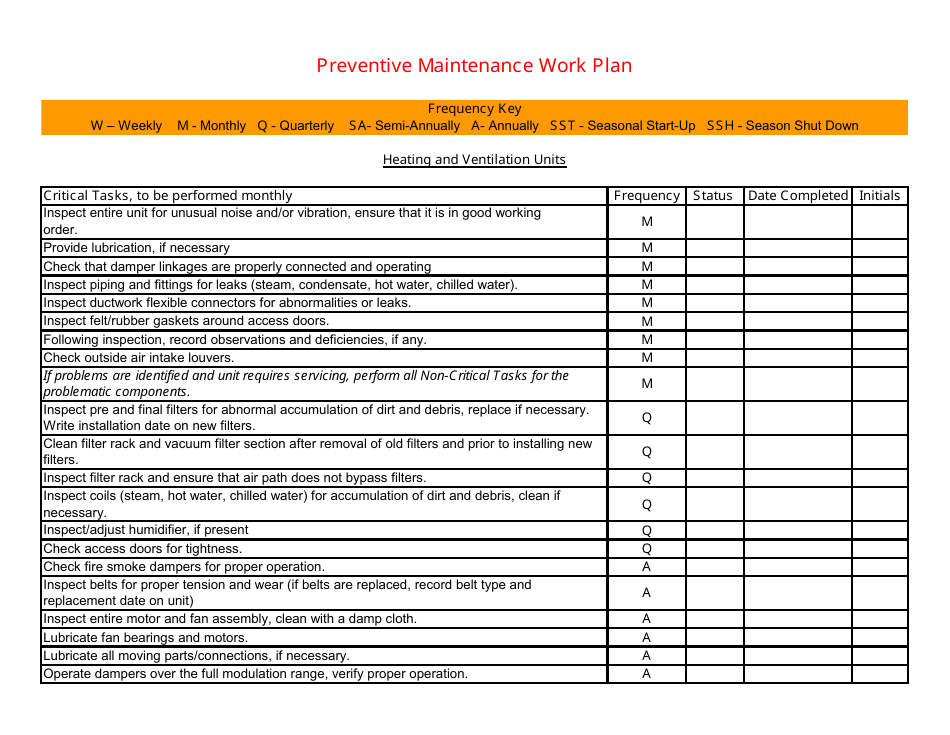

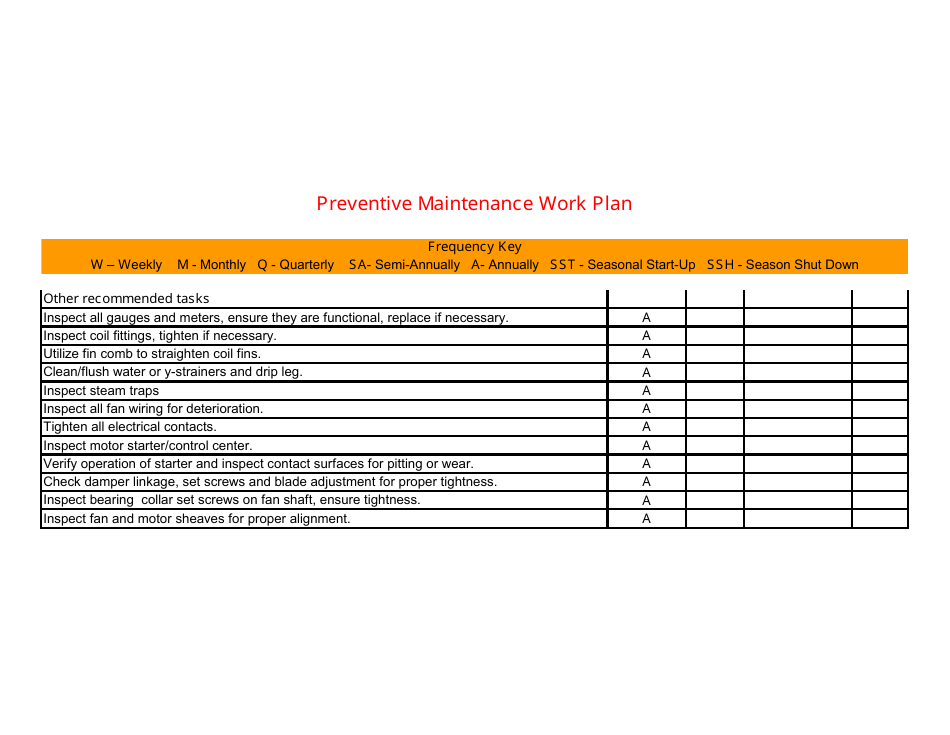

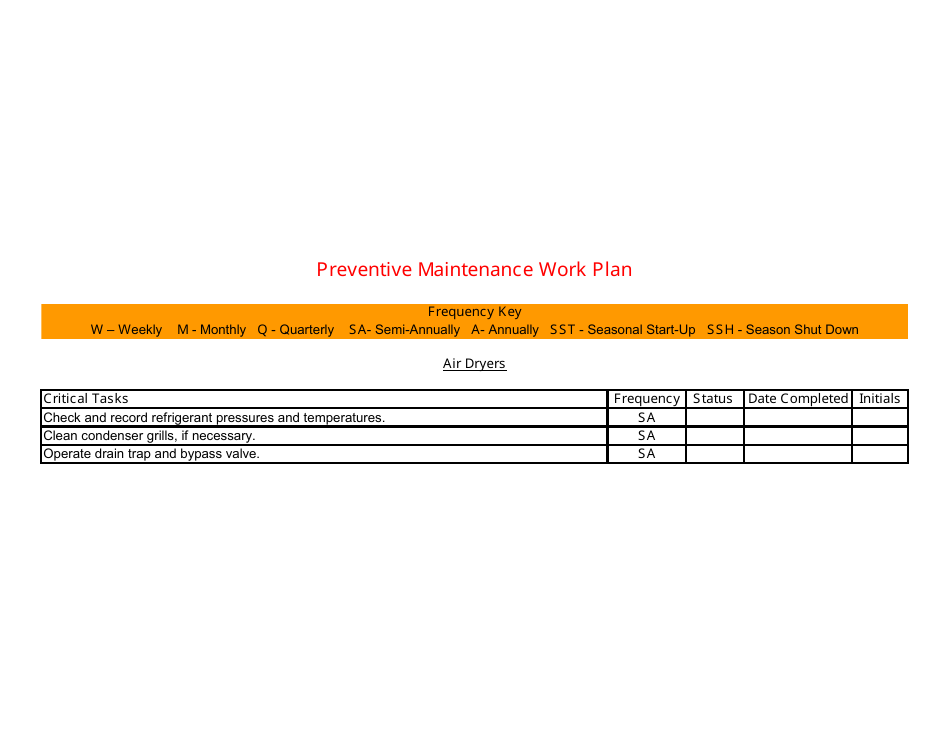

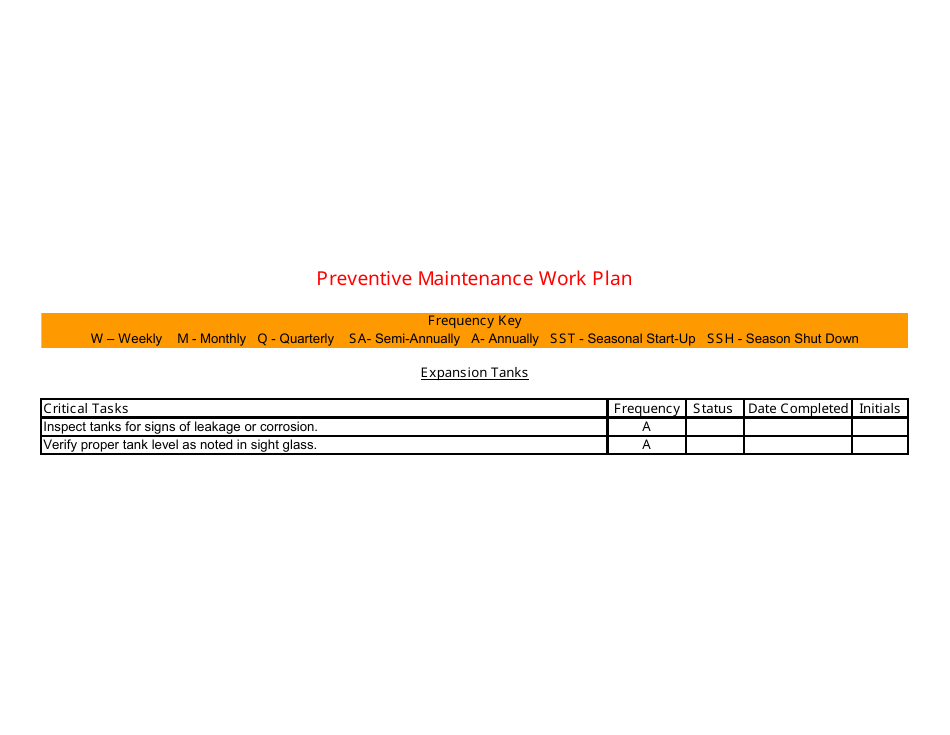

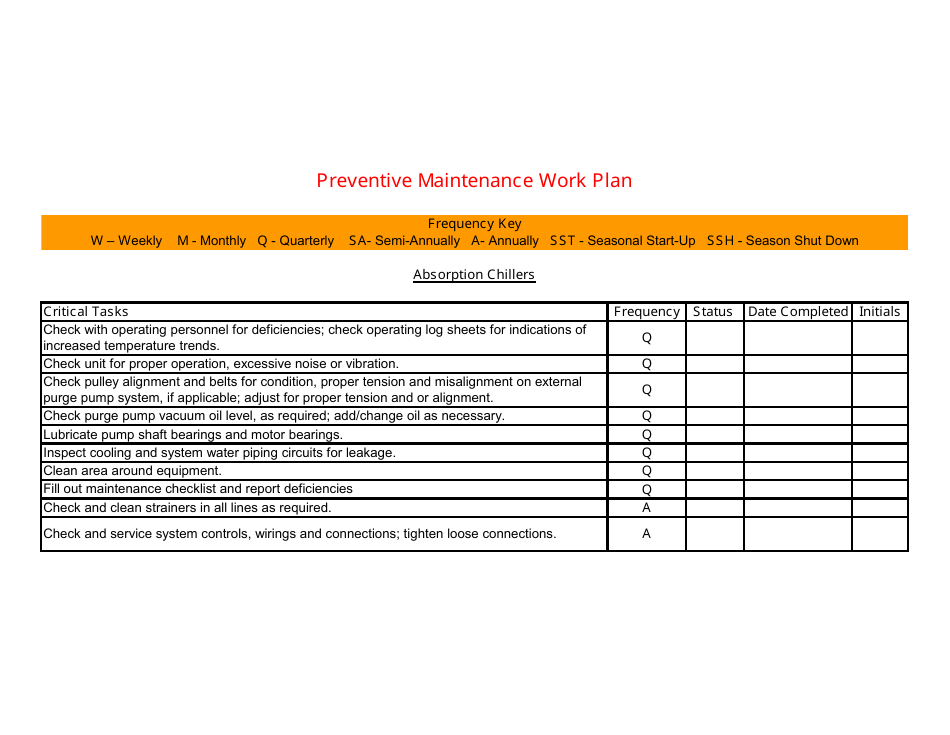

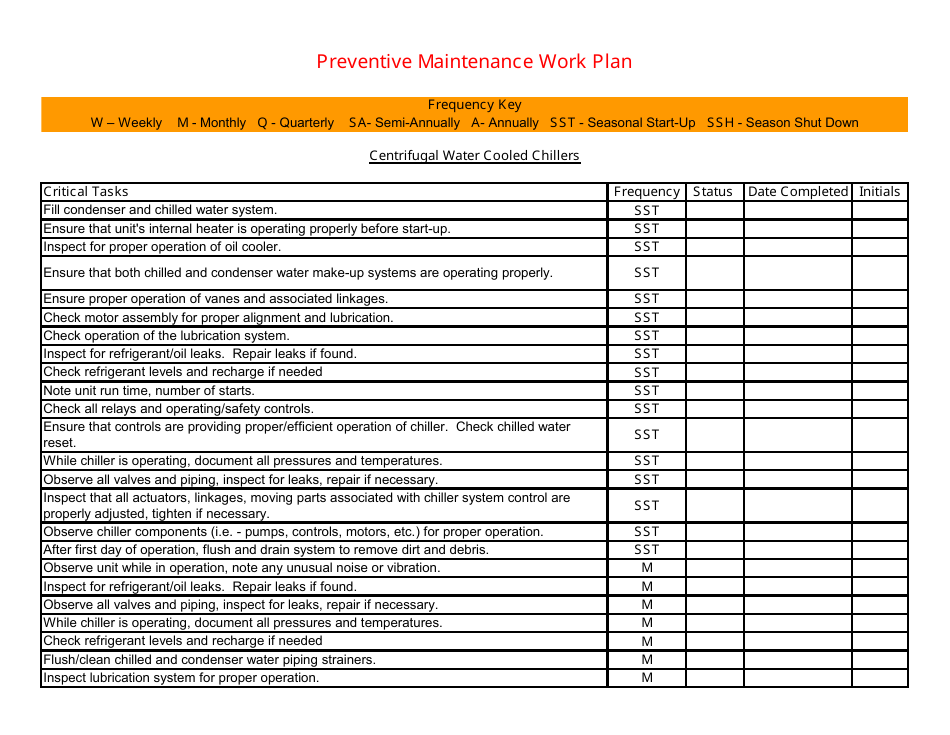

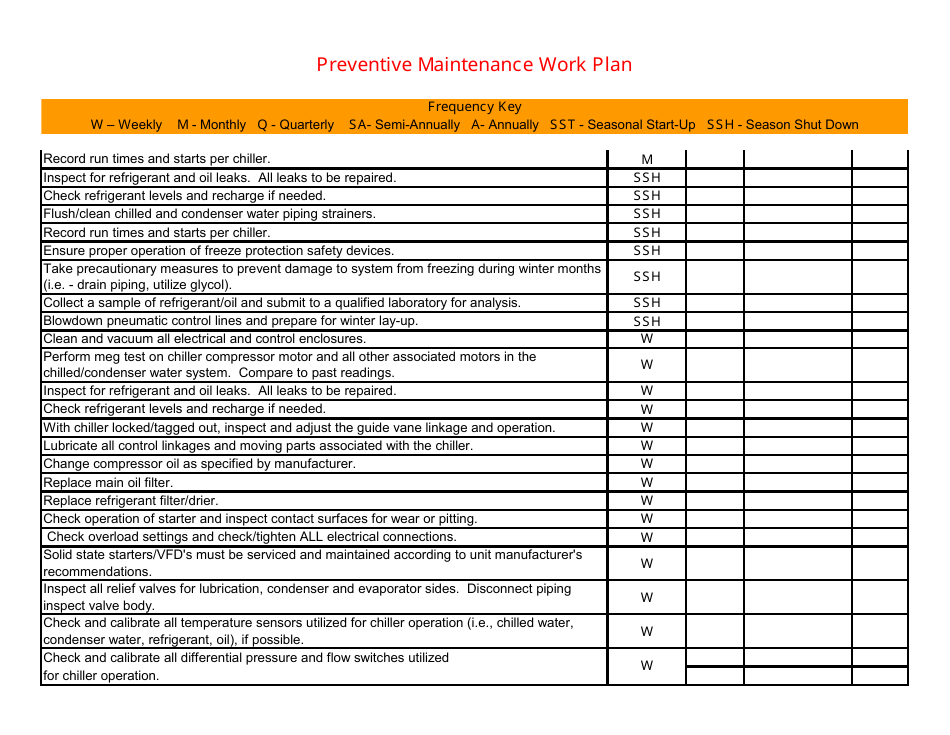

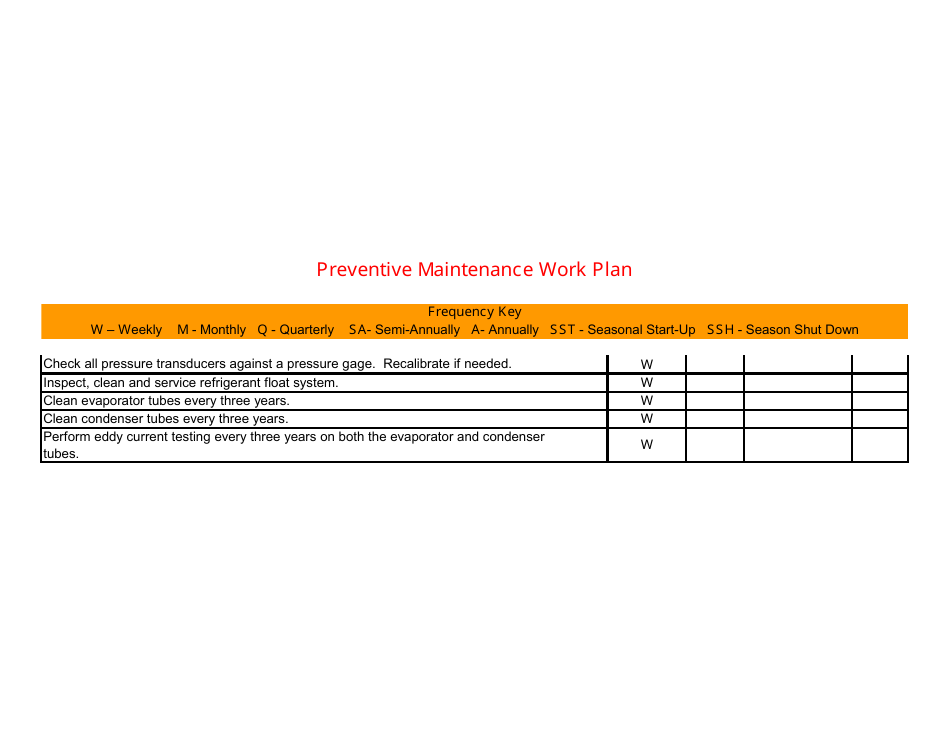

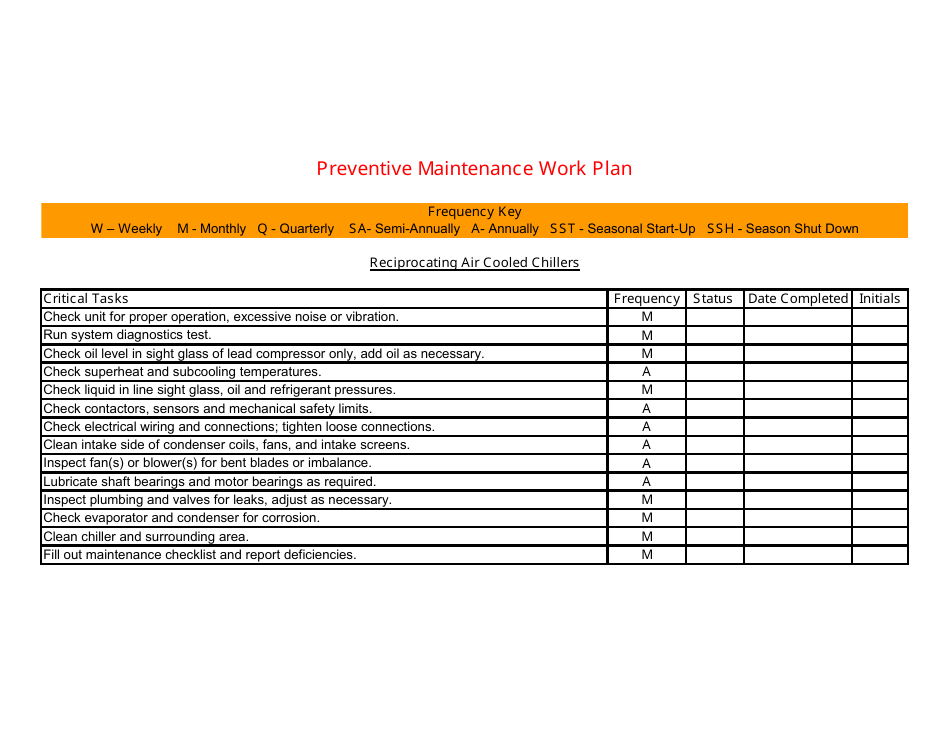

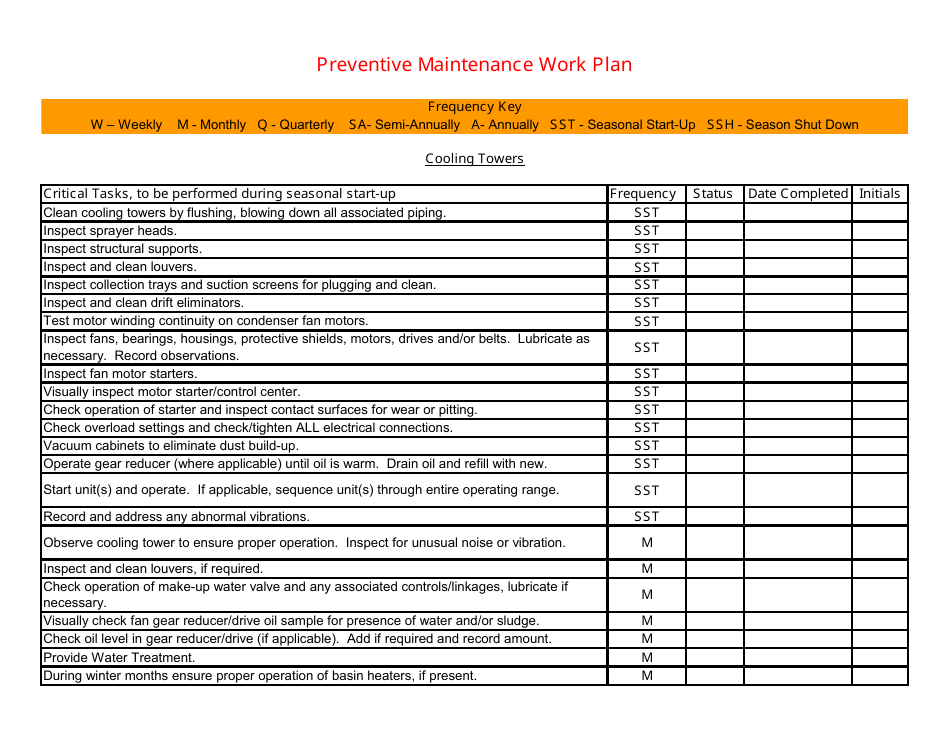

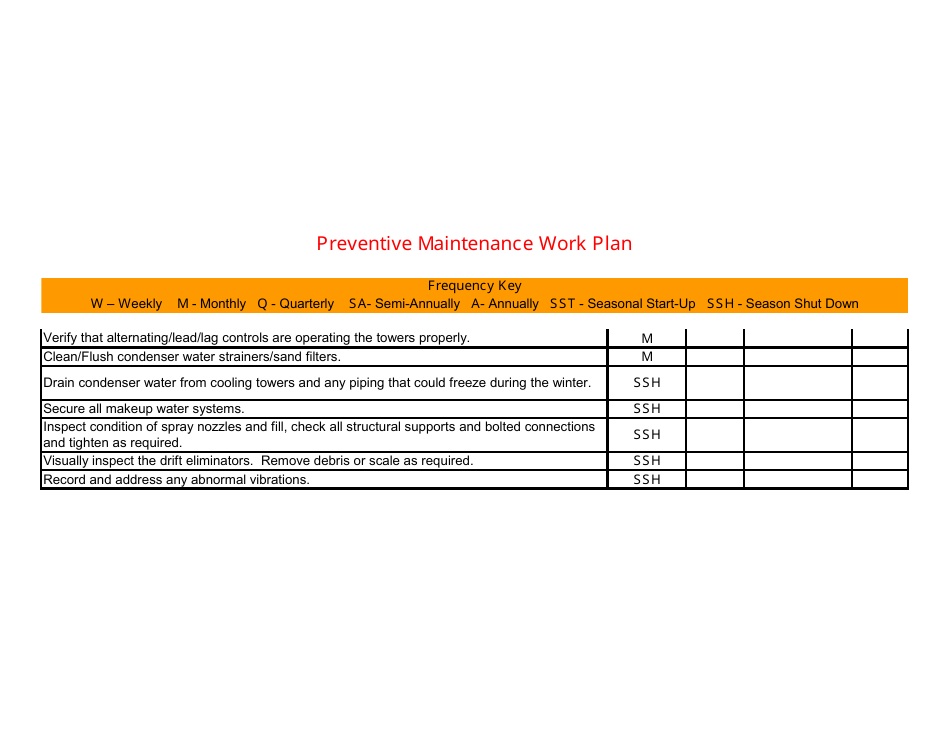

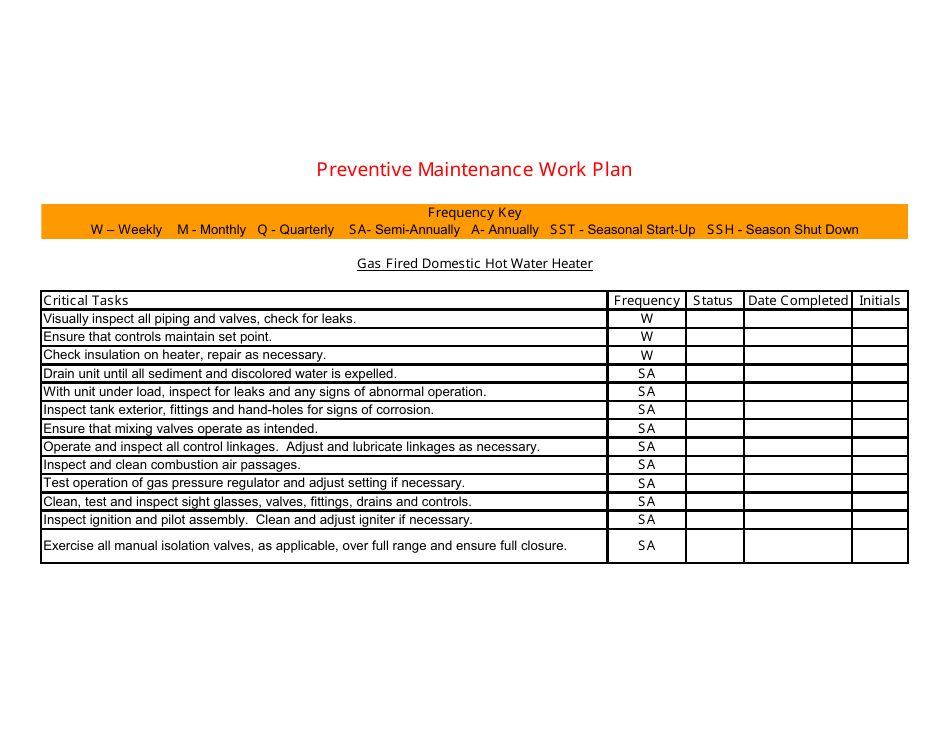

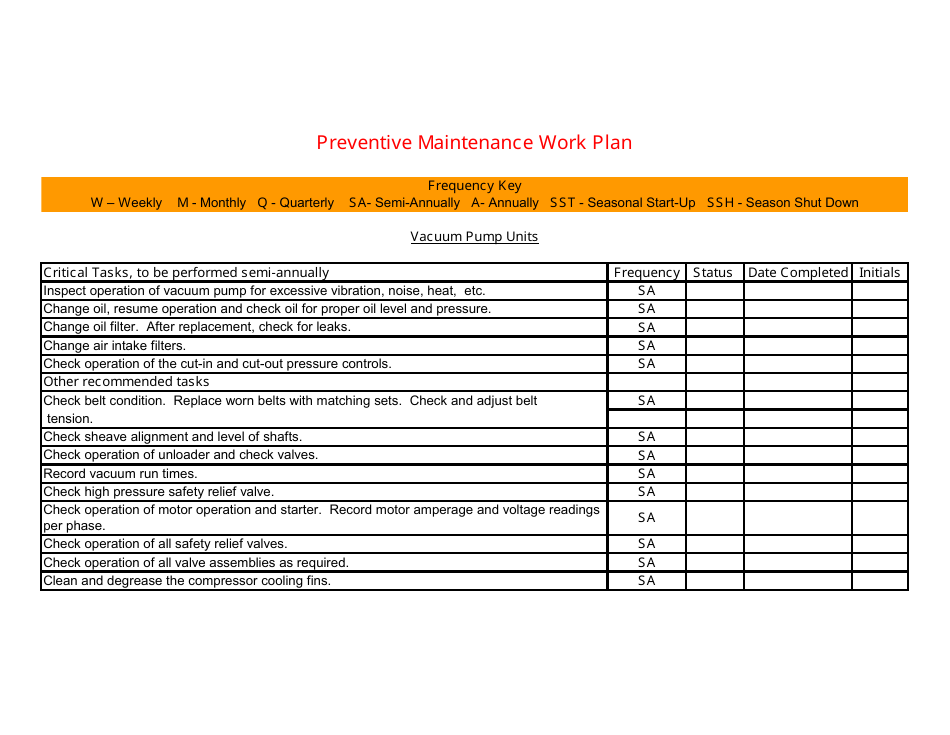

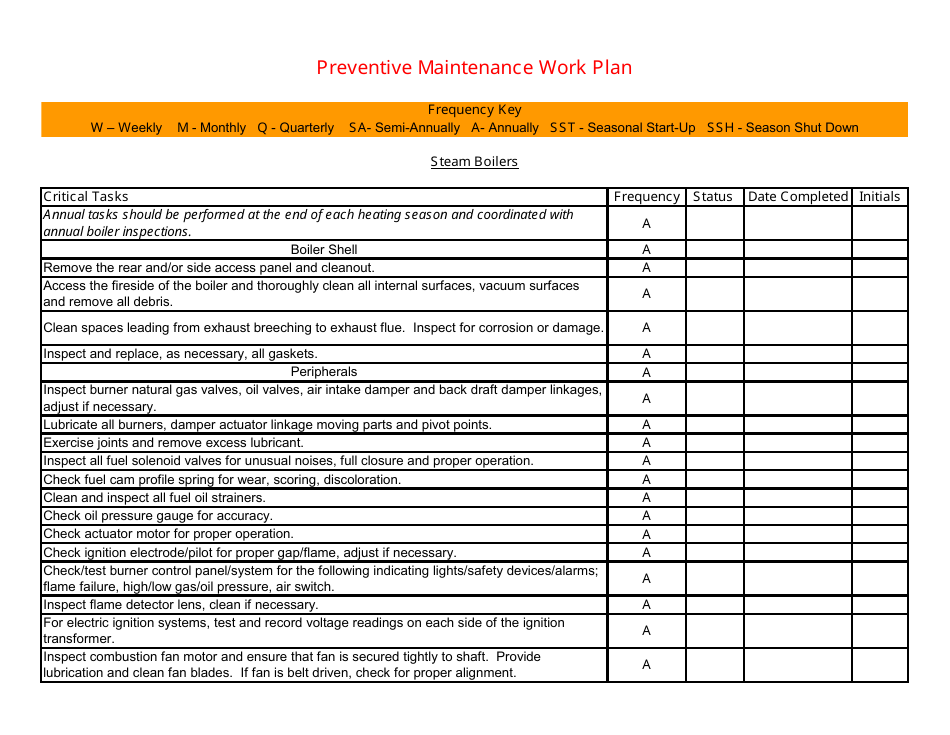

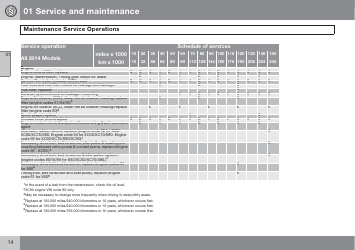

Q: What should be included in a preventive maintenance work plan?

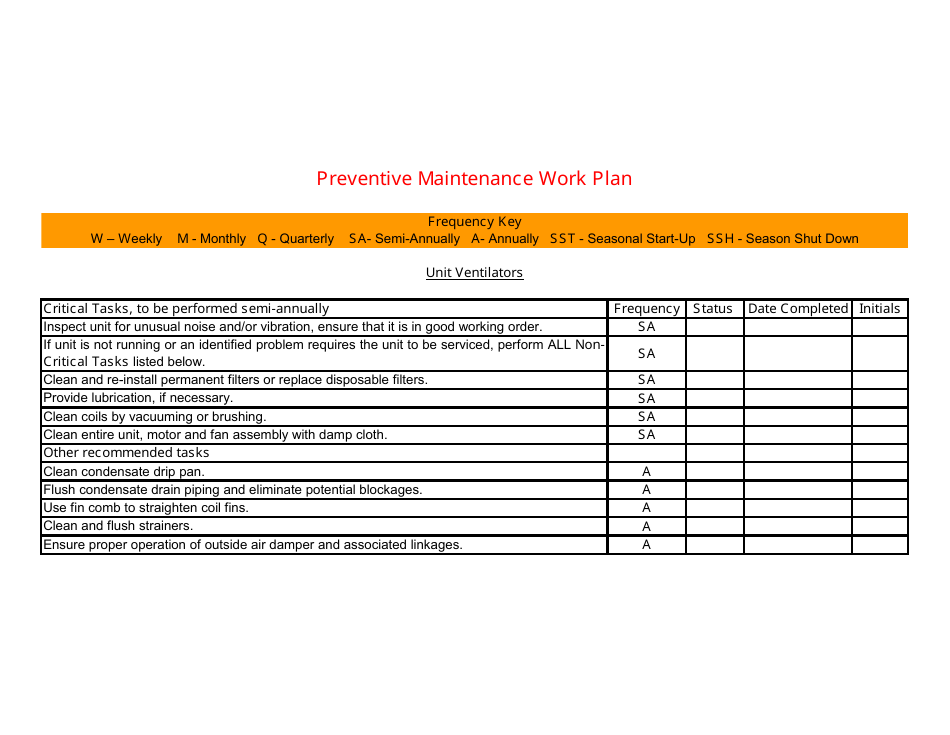

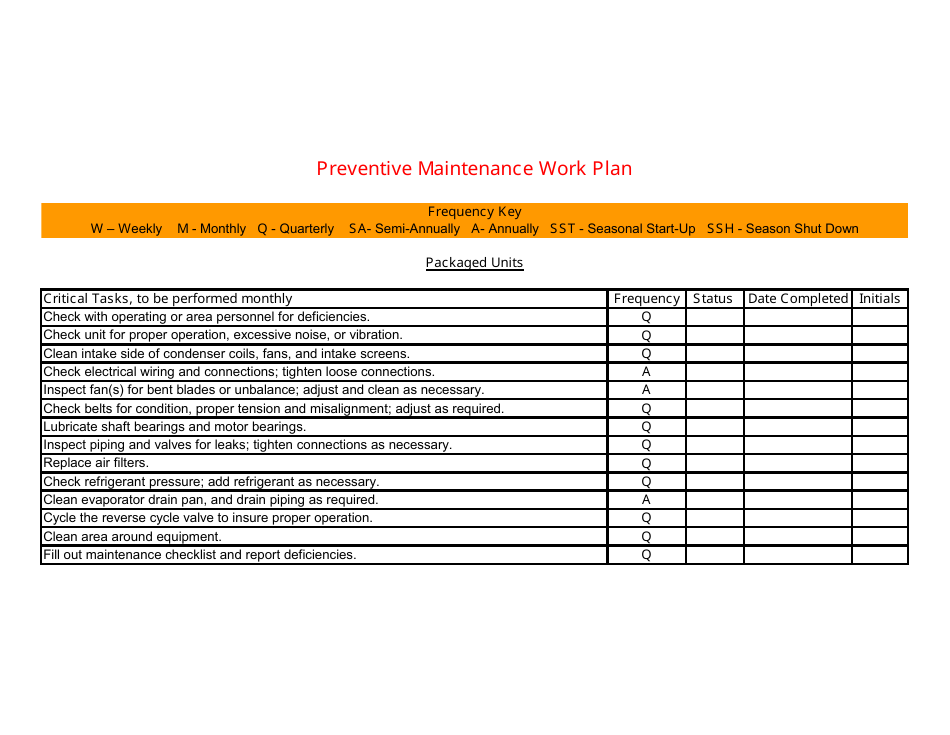

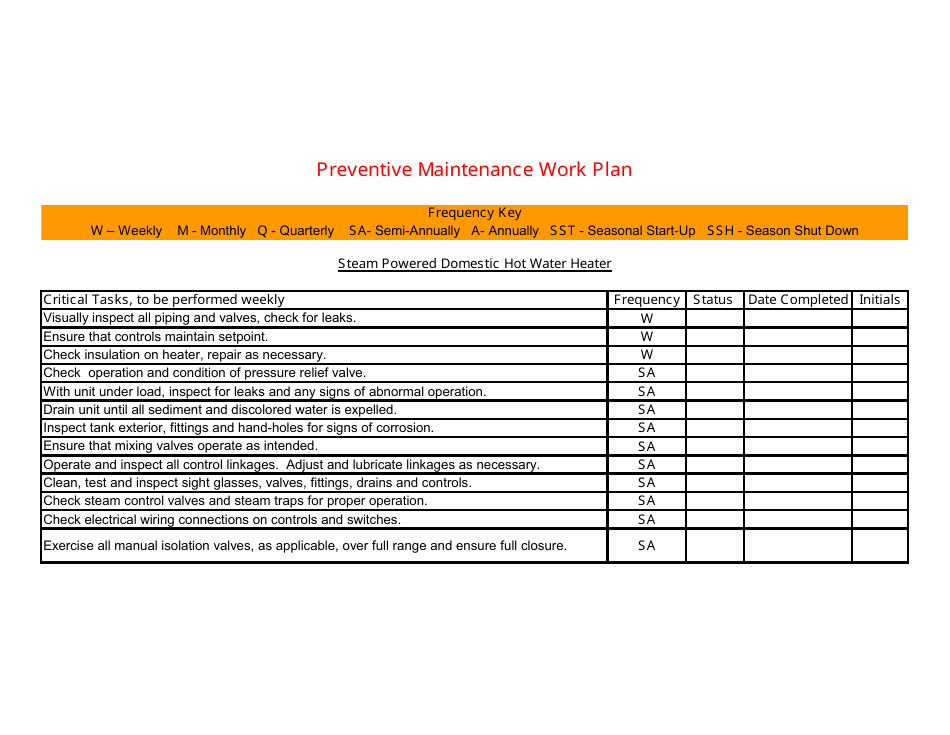

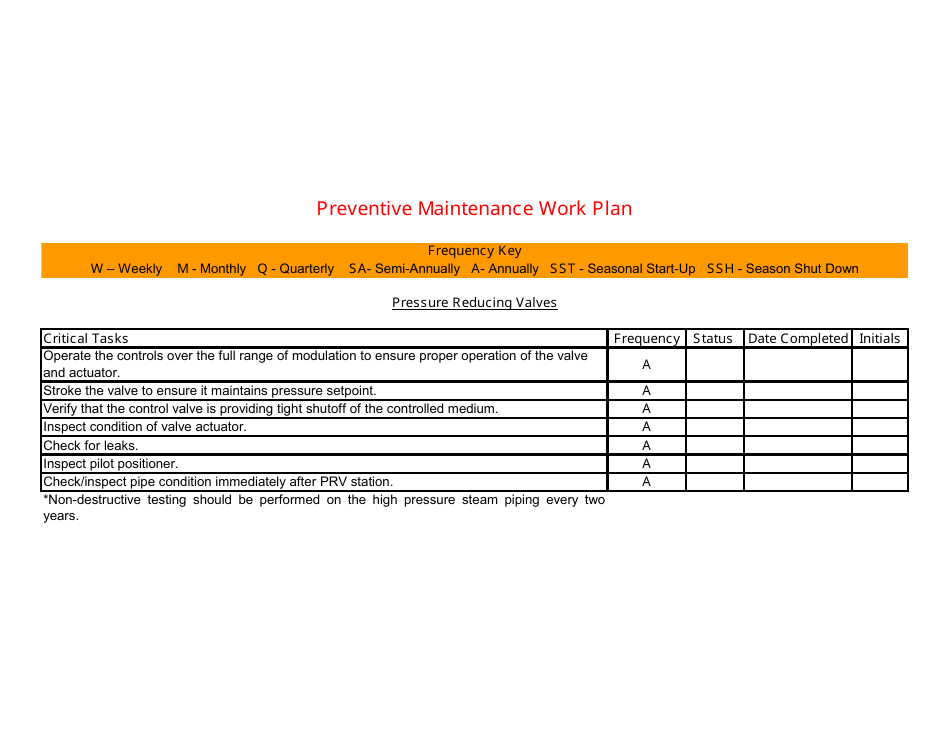

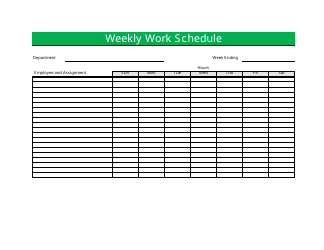

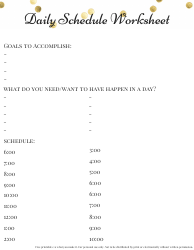

A: A preventive maintenance work plan should include a list of equipment and facilities to be maintained, a schedule for maintenance tasks, details of maintenance procedures, and responsible personnel.

Q: How often should preventive maintenance tasks be performed?

A: The frequency of preventive maintenance tasks will depend on the type of equipment or facility being maintained. It could range from daily to annually, based on manufacturer recommendations and industry best practices.

Q: Who is responsible for implementing a preventive maintenance work plan?

A: The responsibility for implementing a preventive maintenance work plan can vary depending on the organization. It could be assigned to a maintenance team, facility manager, or designated staff members.

Q: Are there any tools or software available to help create a preventive maintenance work plan?

A: Yes, there are various tools and software available that can help create and manage a preventive maintenance work plan. These tools often offer features like scheduling, reminders, and tracking of maintenance tasks.