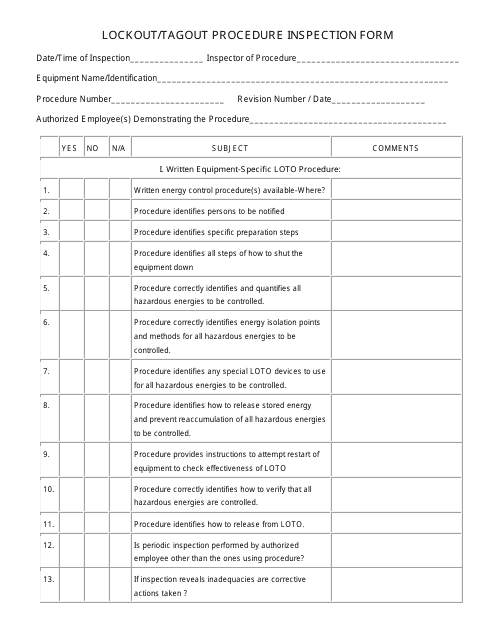

Lockout / Tagout Procedure Inspection Form

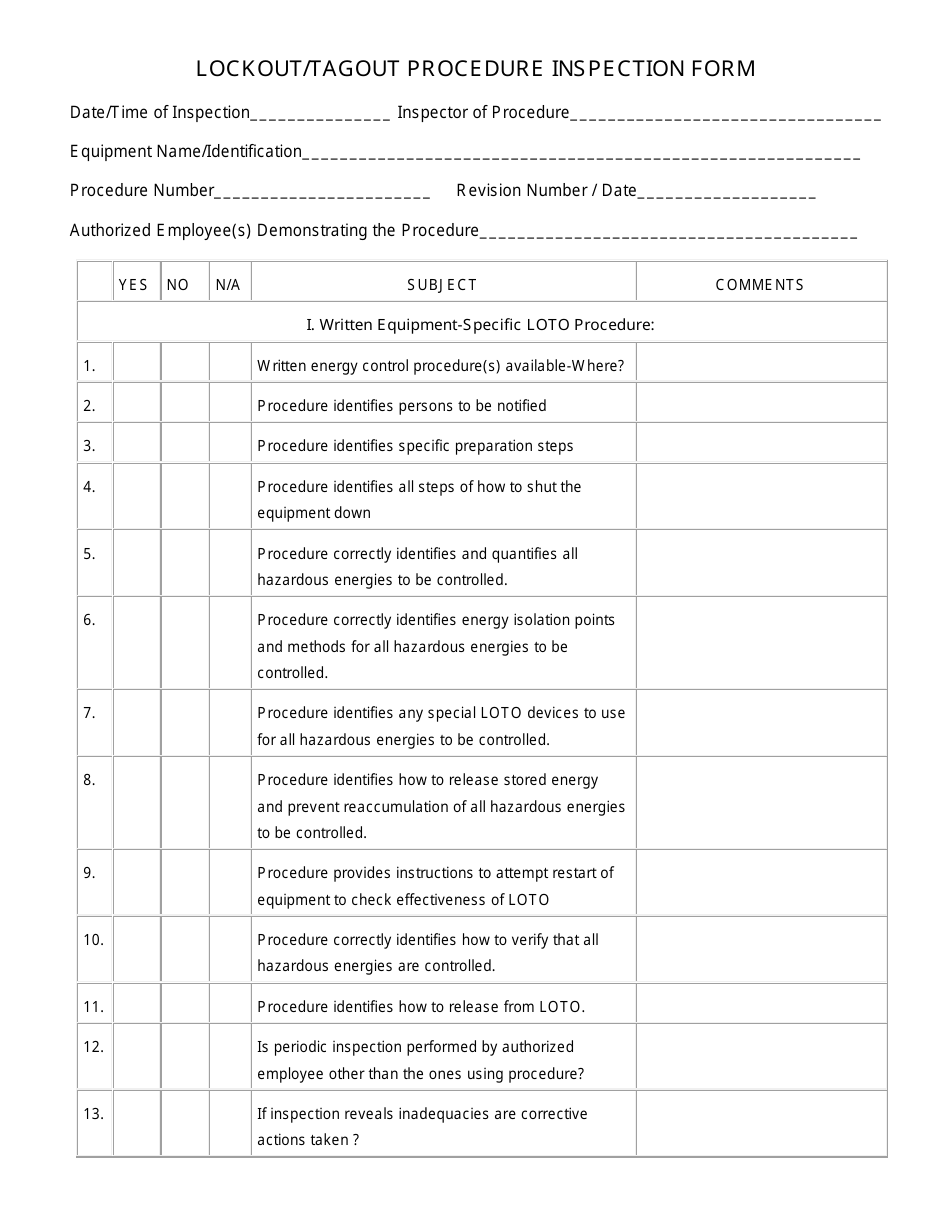

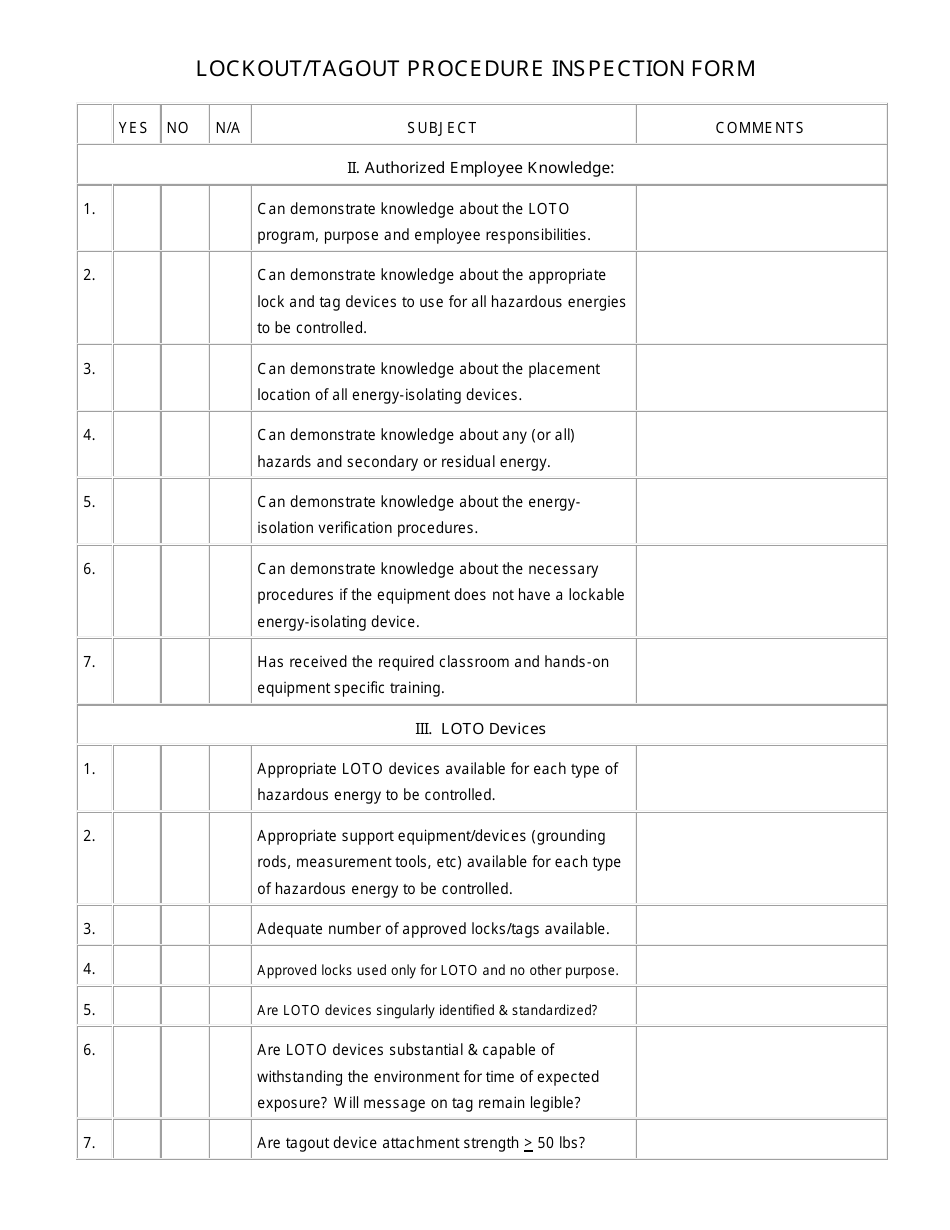

The Lockout/Tagout Procedure Inspection Form is used to ensure the safety of workers while performing maintenance or repairs on equipment or machinery. This procedure involves placing locks and tags on the energy sources of the equipment to prevent unintentional startup or release of stored energy. The inspection form is used to verify that all required steps in the lockout/tagout process have been followed correctly and that the equipment is properly isolated and secured. It helps to prevent accidents, injuries, and fatalities by ensuring that the equipment is safe to work on.

The lockout/tagout procedure inspection form is typically filed by the authorized personnel responsible for conducting the inspection. This may include maintenance technicians, safety officers, or any designated individuals trained in lockout/tagout procedures. The form is usually submitted to the appropriate department or authority within the organization, such as the safety or maintenance department.

FAQ

Q: What is a lockout/tagout procedure?

A: A lockout/tagout procedure is a safety protocol that is used to control hazardous energy sources during maintenance or servicing of equipment.

Q: Why is a lockout/tagout procedure important?

A: A lockout/tagout procedure is important because it helps prevent unexpected startup of equipment or release of stored energy, which can cause serious injuries or fatalities.

Q: What is the purpose of a lockout/tagout procedure inspection form?

A: The purpose of a lockout/tagout procedure inspection form is to ensure that all safety measures are followed correctly during the equipment lockout/tagout process.

Q: What information is typically included in a lockout/tagout procedure inspection form?

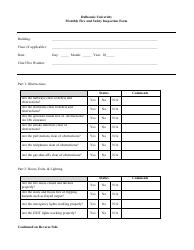

A: A lockout/tagout procedure inspection form usually includes details such as date and time of inspection, equipment or machinery involved, names of authorized employees performing the lockout/tagout, description of lockout/tagout devices used, and any observations or findings related to the procedure.

Q: Who is responsible for completing a lockout/tagout procedure inspection form?

A: Typically, a qualified authorized employee or a safety officer is responsible for completing a lockout/tagout procedure inspection form.

Q: How often should lockout/tagout procedure inspections be conducted?

A: Lockout/tagout procedure inspections should be conducted on a regular basis, as specified by the organization's safety policies and regulations. Typically, inspections are performed before each lockout/tagout procedure and periodically throughout the year.

Q: What are the consequences of not following a lockout/tagout procedure?

A: The consequences of not following a lockout/tagout procedure can be severe, including serious injuries or fatalities due to unexpected release of energy or startup of equipment.