Visual Inspection Templates

Visual Inspection refers to the process of conducting a thorough examination of a certain object or environment using only the sense of sight. It plays a crucial role in various industries and sectors, ensuring that objects, structures, and equipment meet the required standards and are free from any defects or damages.

At its core, visual inspection involves visually assessing the condition, quality, and performance of an object or system. It enables inspectors or technicians to identify any potential issues, such as structural damage, faulty components, or safety hazards. By closely examining the item or area in question, inspectors can gather valuable information that helps them make informed decisions and take the necessary actions to address any problems.

One of the key benefits of visual inspection is its versatility. It can be applied in various contexts, ranging from manufacturing and construction to maintenance and safety inspections. Whether it's inspecting machinery on a manufacturing line, monitoring the integrity of tanks, or ensuring compliance with safety standards, visual inspection plays a vital role in maintaining quality and preventing failures.

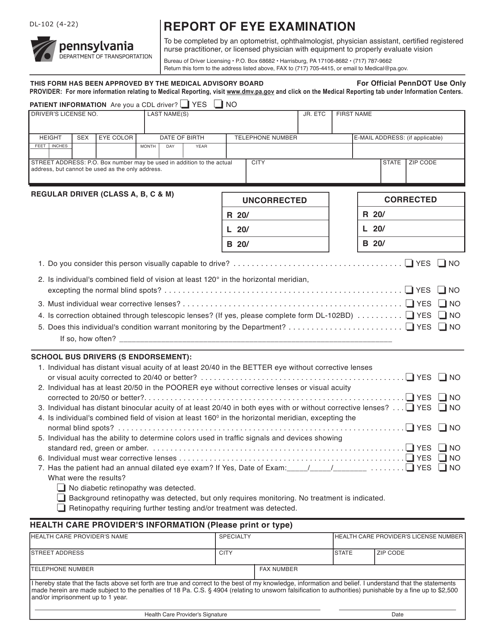

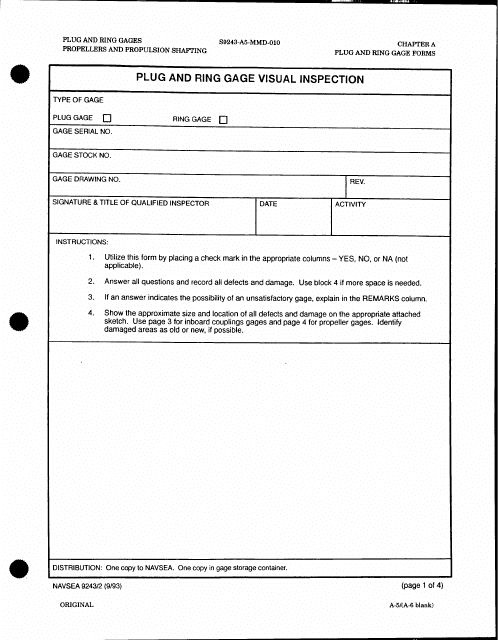

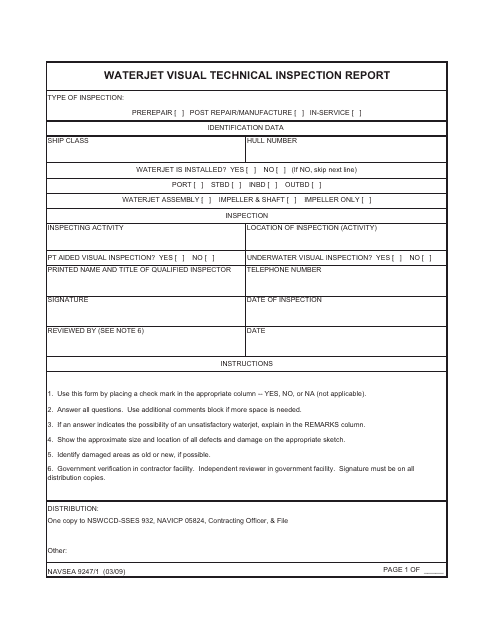

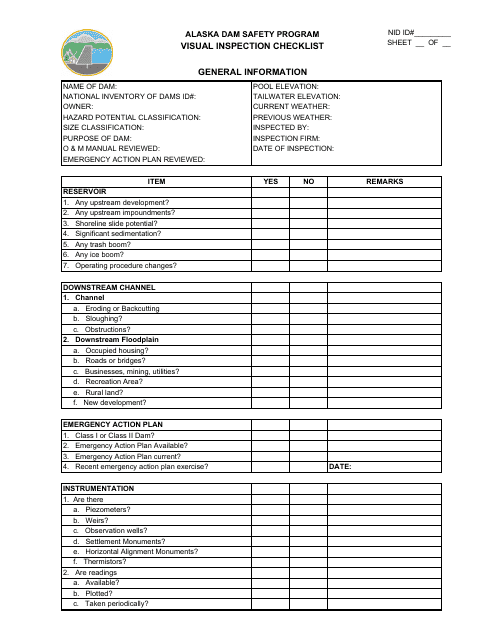

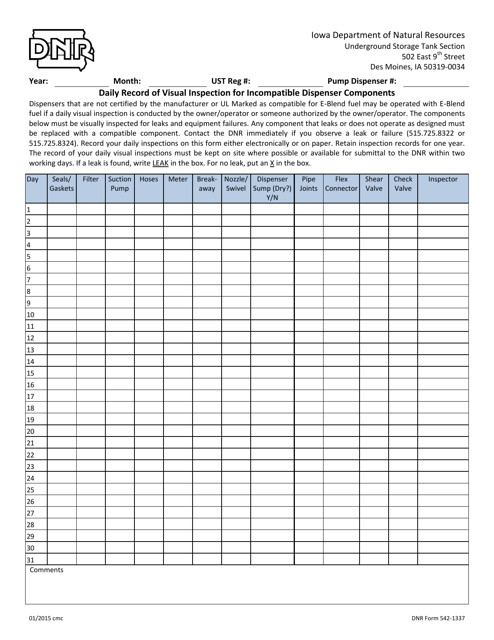

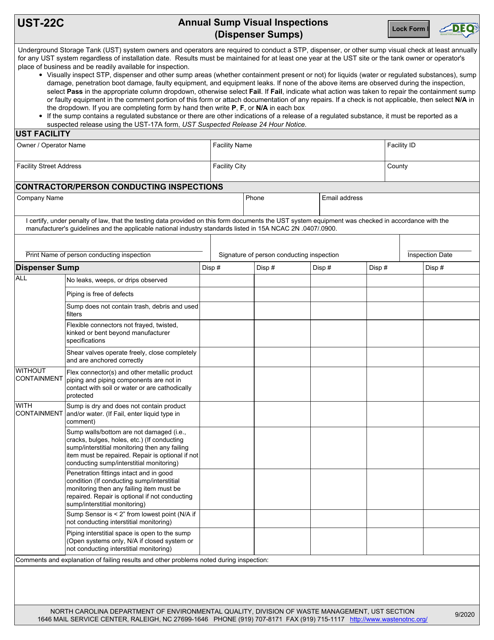

To streamline the visual inspection process, many organizations utilize standardized forms and reports. These documents, such as the monthly visual inspection for double-walled tanks or the daily record of visual inspection for incompatible dispenser components, serve as comprehensive tools for recording and documenting the findings of visual inspections. They help maintain accurate and organized records, facilitating efficient analysis and follow-up actions.

Visual inspection forms are designed to capture important details during inspections, including observations, measurements, and photographs. They provide a structured framework for inspectors to document their findings, ensuring consistency and enabling easy comparison and analysis of data over time.

In essence, visual inspection forms are an integral part of the visual inspection process, helping organizations ensure compliance, maintain quality, and improve safety standards. They enable efficient documentation and tracking of inspections, resulting in enhanced decision-making and increased operational efficiency.

So whether you refer to it as visual inspection, visually inspecting objects, or using visual inspection forms, the process remains a fundamental aspect of quality assurance, safety assurance, and overall maintenance in various industries.

Documents:

18

This form is used for visual inspection of plug and ring gages.

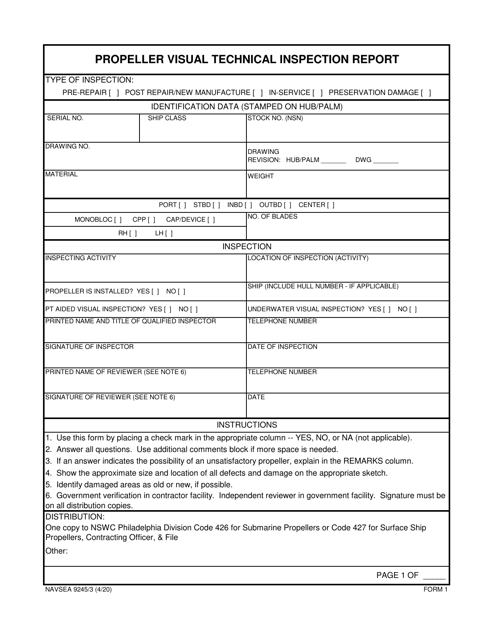

This document is a form used for the visual technical inspection of waterjet systems. It is used to report any observations or findings during the inspection process.

This document provides a checklist for visually inspecting dams in Alaska as part of the Dam Safety Program. It helps ensure the safety and integrity of the dams.

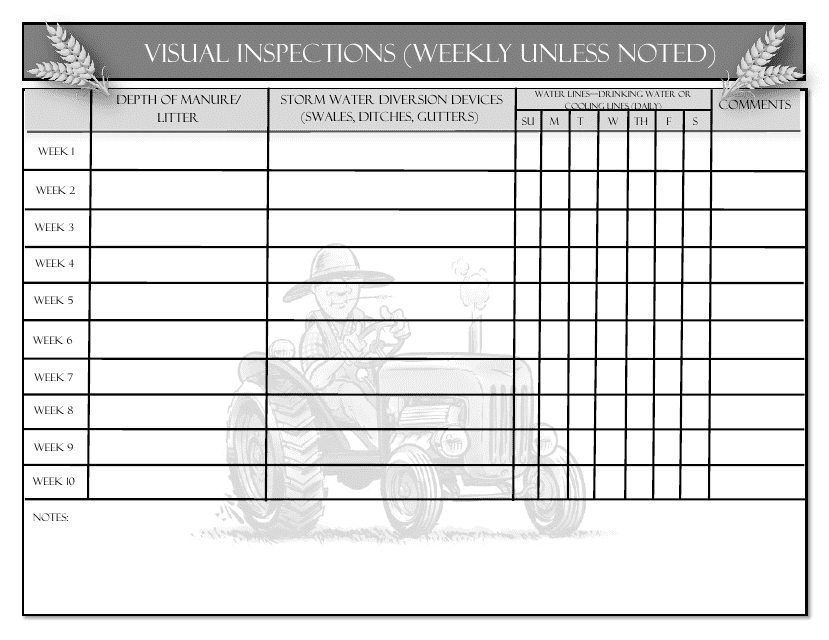

This form is used for conducting weekly visual inspections in the state of Delaware.

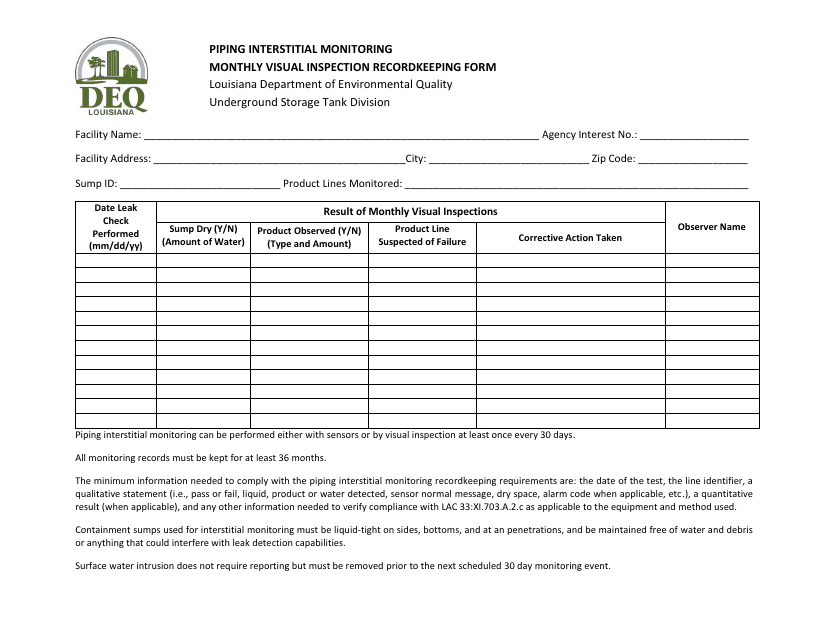

This form is used for keeping a record of monthly visual inspections for piping interstitial monitoring in Louisiana.

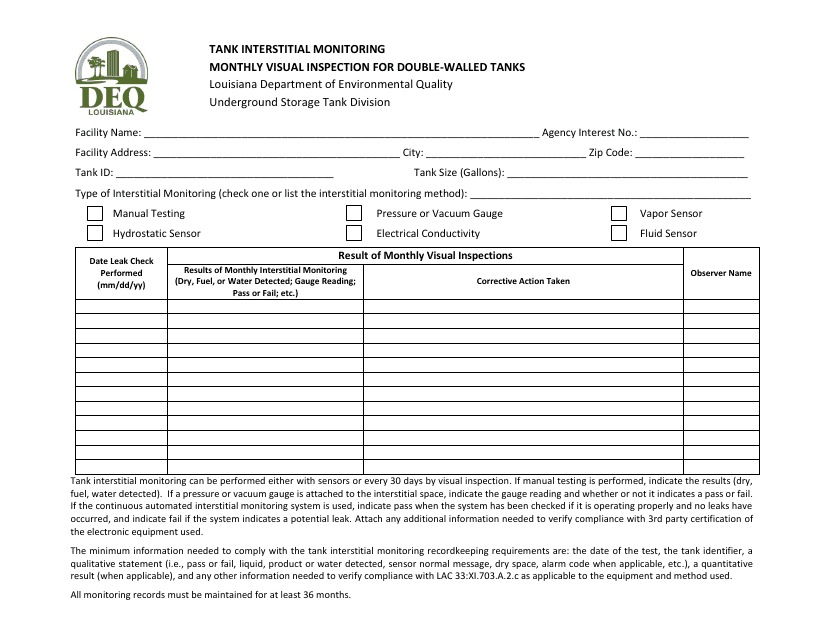

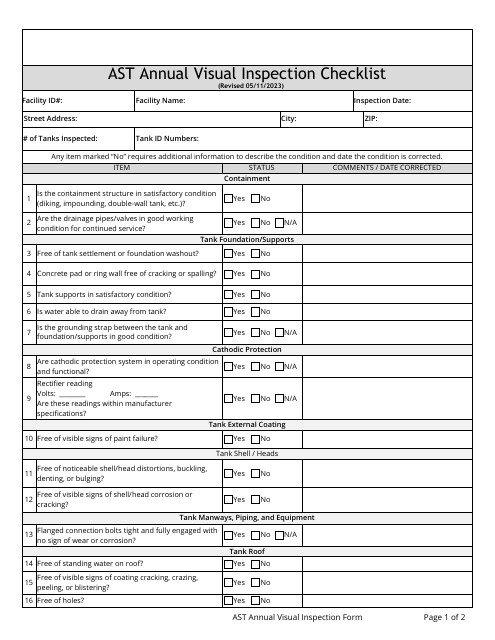

This document describes the monthly visual inspection process for double-walled tanks used for tank interstitial monitoring in Louisiana.

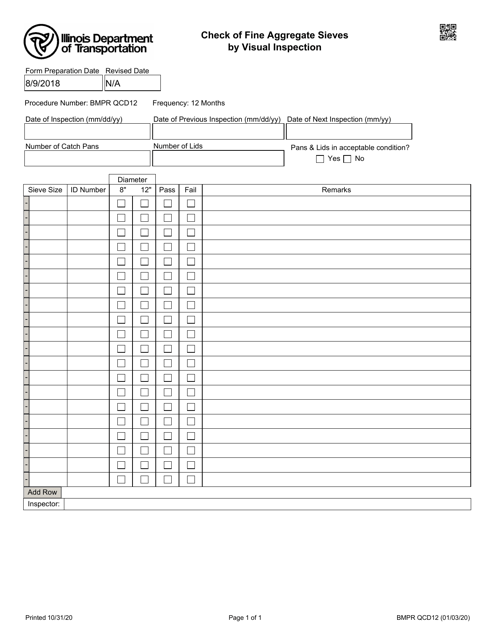

This document form is used for visually inspecting the fine aggregate sieves in Illinois.

This form is used for recording daily visual inspections of incompatible dispenser components in Iowa.

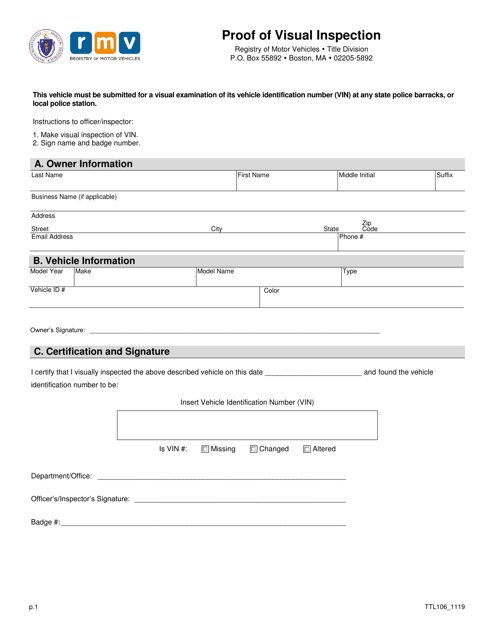

This form is used for providing proof of visual inspection in the state of Massachusetts. It is typically required for certain types of inspections, such as for buildings or vehicles, to ensure they meet safety standards.

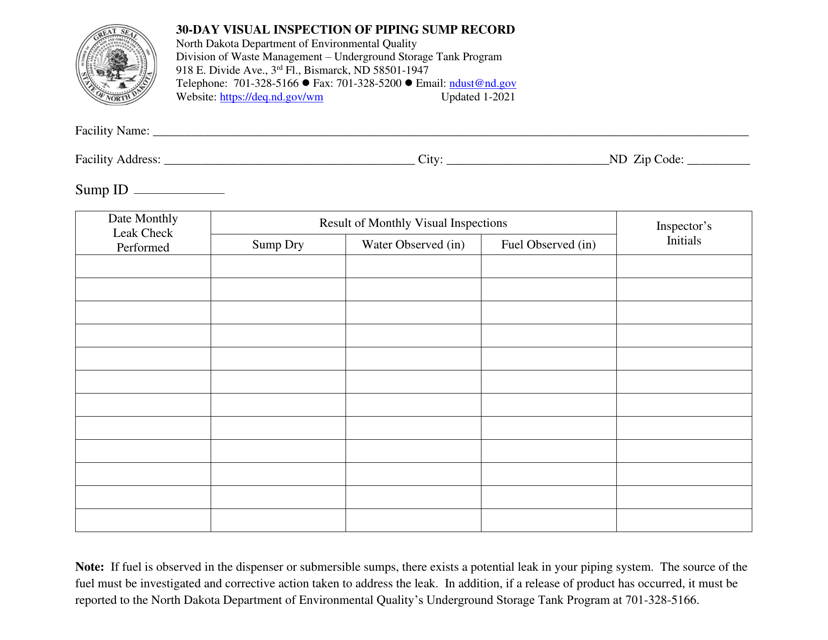

This document is for recording the 30-day visual inspection of piping sump in North Dakota. It is used to keep track of any issues or maintenance needs for the sump system.

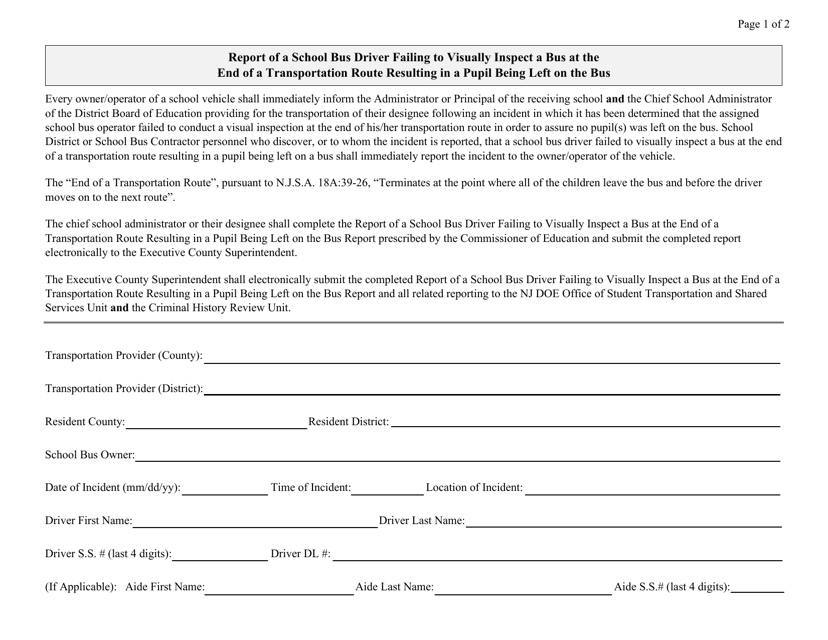

This report is about a school bus driver failing to visually inspect the bus after a transportation route, which led to a student being left on the bus. It happened in New Jersey.

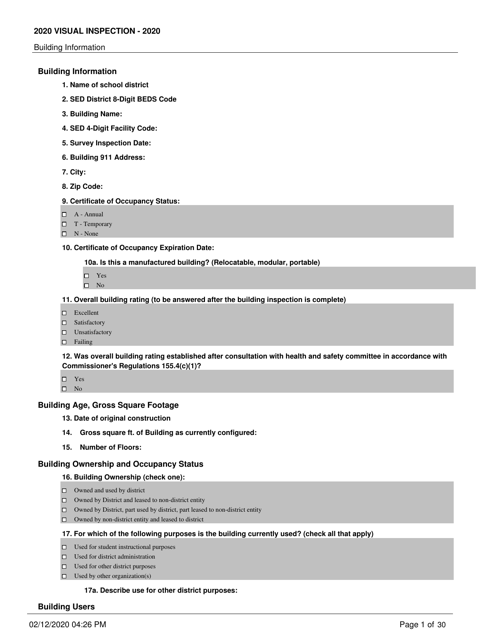

This type of document is used for conducting a visual inspection in the state of New York. It may involve examining a property, infrastructure, or other physical objects to assess their condition or compliance with regulations.

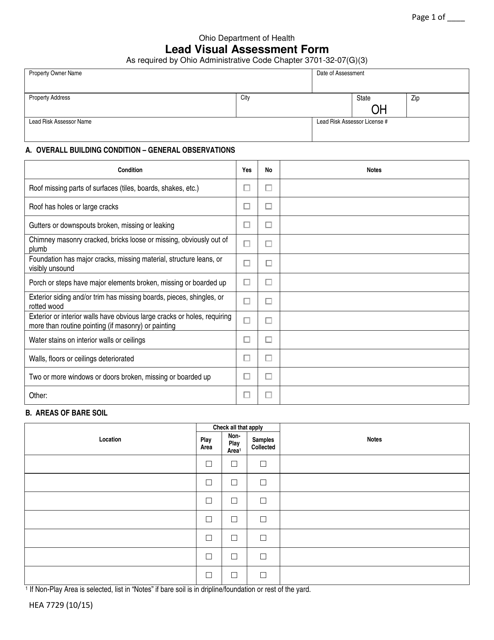

This form is used for conducting lead visual assessments in Ohio.

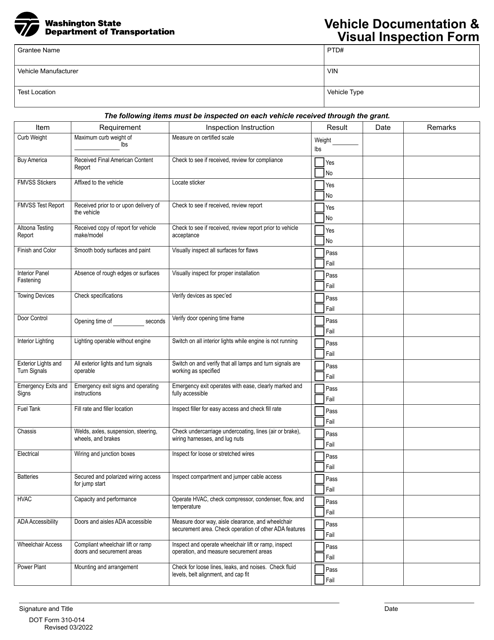

This Form is used for vehicle documentation and visual inspection in Washington. It is a required form for registering a vehicle in the state.