Aggregate Testing Templates

Whether you call it aggregate testing, aggregate tests, or any of its alternate names, this collection of documents is essential for assessing the quality and reliability of aggregate materials used in construction projects.

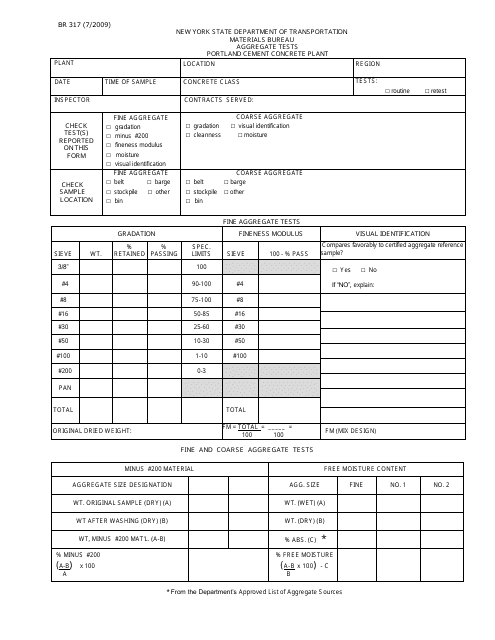

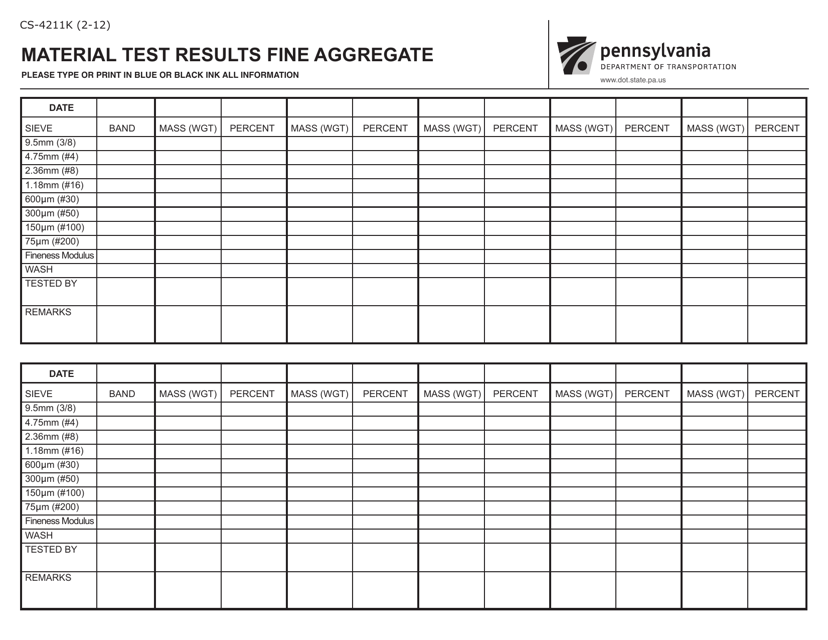

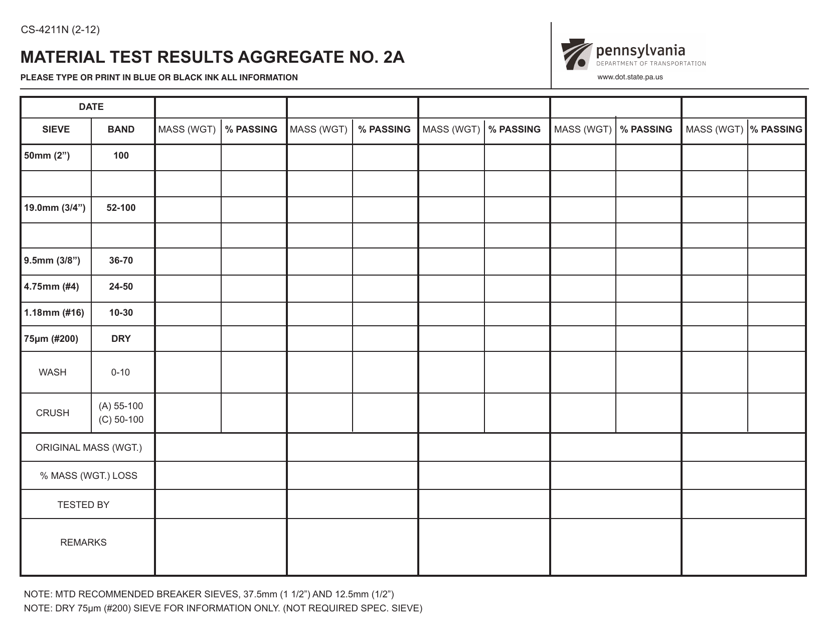

Aggregate testing is a crucial step in ensuring the durability and performance of portland cement concrete plants. The Form BR317, used in New York, enables thorough testing of aggregate materials, guaranteeing that only the best components are used in construction projects. Similarly, Form CS-4211K and Form CS-4211N, utilized in Pennsylvania, provide material test results for fine and coarse aggregate, respectively.

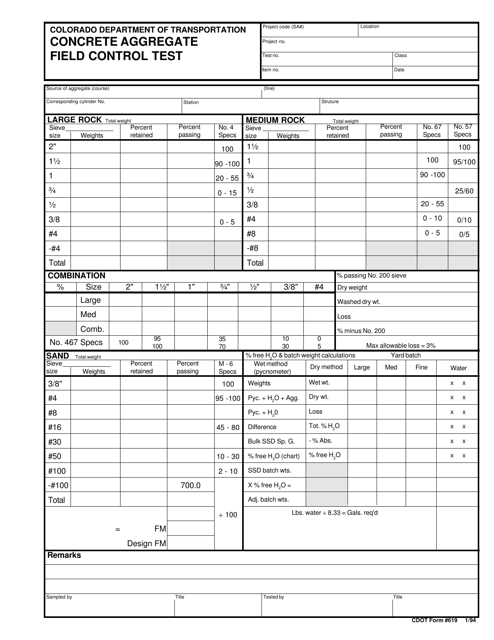

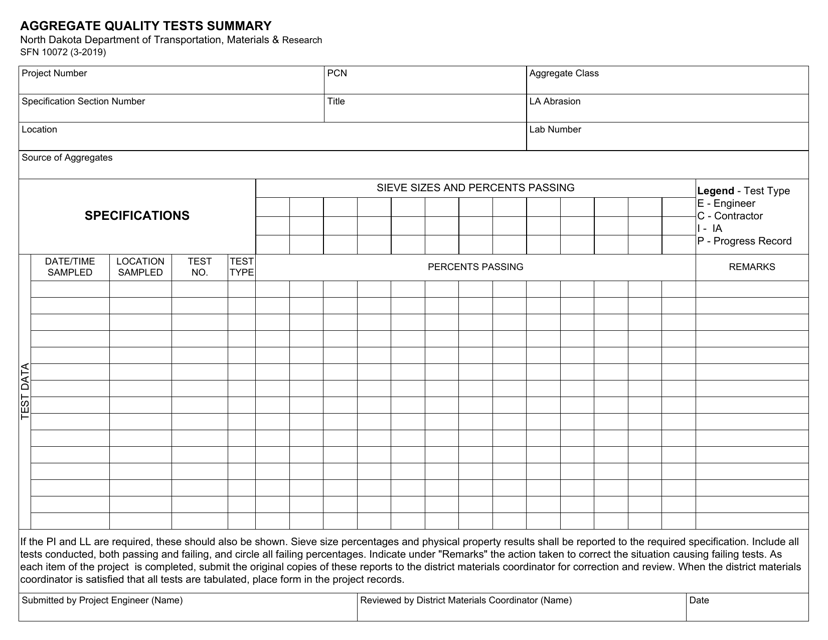

In Colorado, the CDOT Form 619 serves as a concrete aggregate field control test, which confirms that the aggregate materials meet the required standards and specifications. Meanwhile, in North Dakota, the Form SFN10072 aggregates quality tests summary offers a comprehensive overview of the quality control measures taken during aggregate testing.

With these documents and many others in this aggregate testing collection, construction professionals can verify the performance and quality of the aggregate materials they utilize, guaranteeing the longevity and safety of their projects.

Documents:

6

This form is used for conducting aggregate tests at a Portland cement concrete plant in New York. It helps ensure the quality of the concrete being produced.

This form is used for documenting the material test results of fine aggregate in Pennsylvania.

This form is used for reporting material test results for Aggregate No. 2a in Pennsylvania.

This form is used for conducting field control tests on concrete aggregate in Colorado.

This Form is used for summarizing the results of aggregate quality tests in North Dakota.

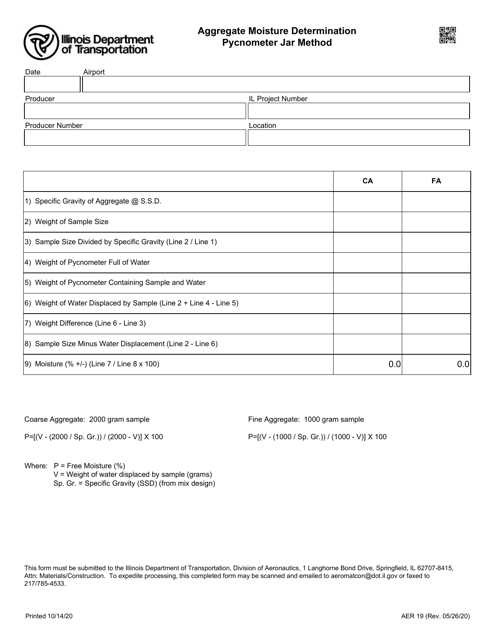

This Form is used for determining aggregate moisture using the pycnometer jar method in the state of Illinois.