Free Inventory Count Sheet Templates

An Inventory Count is the process of counting the quantity of items you have in your inventory. Although this can sometimes be a rather tedious process, it is important nonetheless. Even if you have an automated process that will figure out the inventory quantities for you, you should still carry out a physical Inventory Count as this will give you the most accurate information concerning the quantities in your inventory. In order to do this successfully, you will benefit from using an Inventory Count Sheet.

A standard Inventory Count Sheet template will have the necessary structure for you to do this successfully. The document will assist you in counting every item in a certain place so that you are able to make absolutely sure the statistics properly represent the stock you genuinely possess.

Data may become erroneous over period for a variety of reasons, including incorrect inventory changes, improper placement of items as well as broken or stolen goods. Whenever the numbers you have in your spreadsheet deviate too significantly from the truth, you might not be able to finish a significant order for a major client or you might be faced with a situation where you start purchasing far too many new products while in reality, you still have more than enough in a warehouse somewhere. By performing an Inventory Count, these issues can be eradicated.

For a full list of Inventory Count Sheets please feel free to check out our library below.

How to Do an Inventory Count?

Performing a standardized, regular Inventory Count is arguably amongst the most crucial processes that occur in a business. Ensuring that a business can provide their clients with the services that they desire and when they desire is directly related to performing an Inventory Count which entails the checking of every product for the quality and their numbers. To do this successfully you must:

- To handle the number of goods that will be examined, purchase sufficient counting label s. These counting labels ought to be given identification number to allow for easy identification one by one during the process;

- If component identifiers are absent or the goods appear to be in a state that'd make collecting information challenging, employees must be informed . They will be capable of making any adjustments needed for the future;

- All items that could be kept in containers should be counted in advance . Mark the container with the number before sealing the items inside;

- Put a halt to all storage arrivals, and store any recently acquired items wherever they will not be recorded . If this is not done, you could accidentally count the goods that are coming in which will make your data unreliable and useless;

- Apply the labels to the inspections and keep track of the codes . Make sure all employees who participate are properly taught and knowledgeable about using the labels;

- If there are some irregularities and anomalies in the data, you should devote some time to determine the root cause and eradicate the issue before entering the data into your document.

Haven't found the template you're looking for? Take a look at the related templates below:

Documents:

7

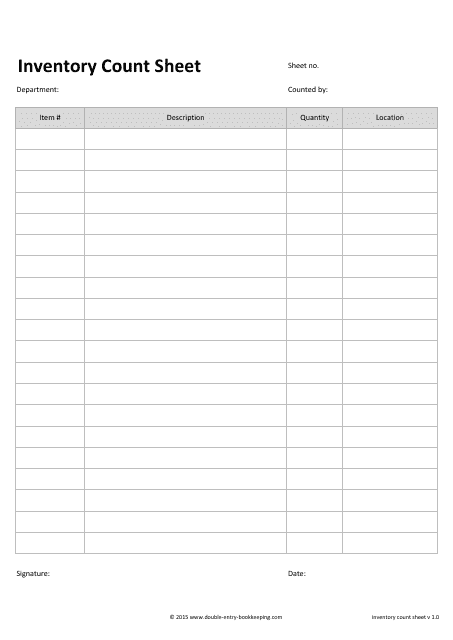

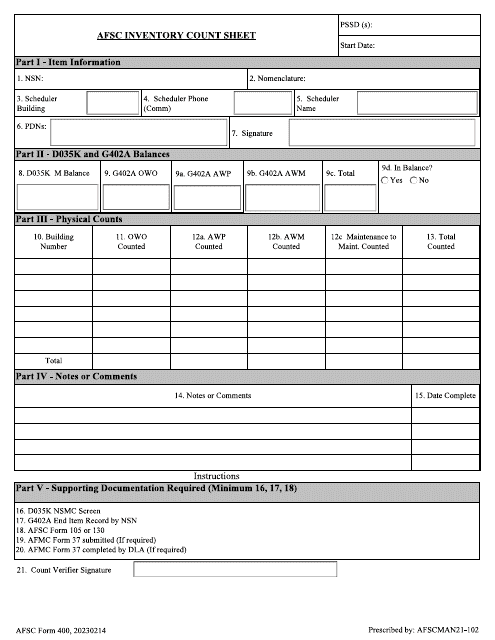

This document is a template for an inventory count sheet. It can be used to track and document the quantity of items on hand in a business or organization.

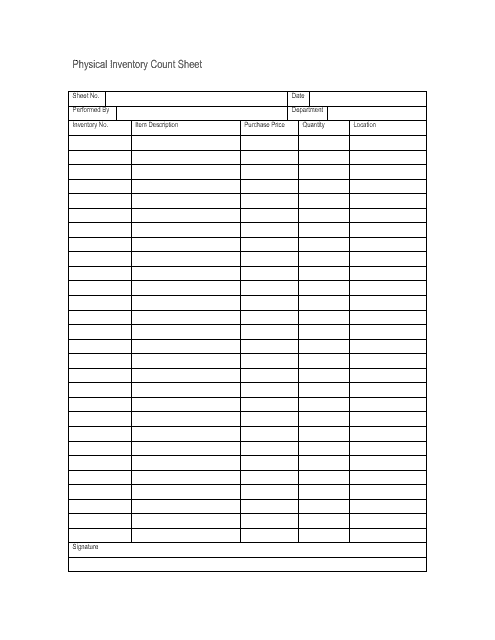

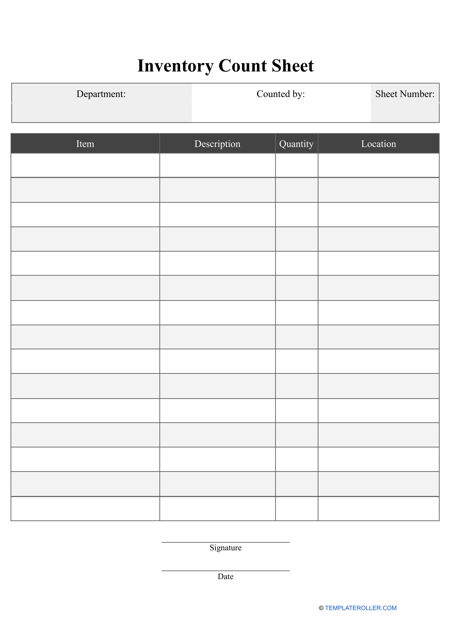

This document is a template for recording a physical inventory count. It helps keep track of stock and ensure accurate inventory management.

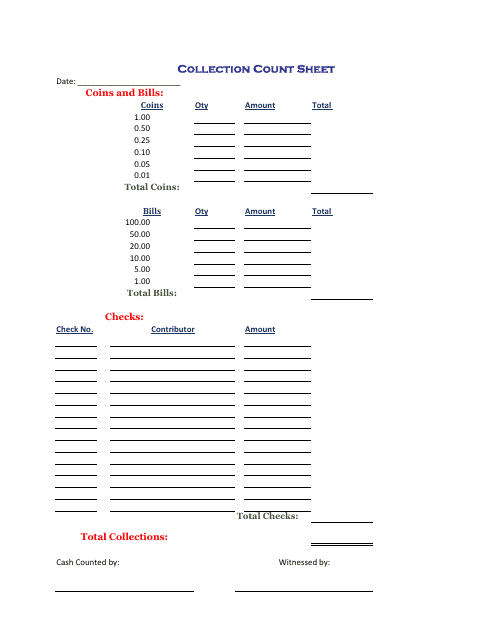

This document is used for tracking and recording the number of items collected during an event or process. It helps to ensure accurate inventory management and record-keeping.

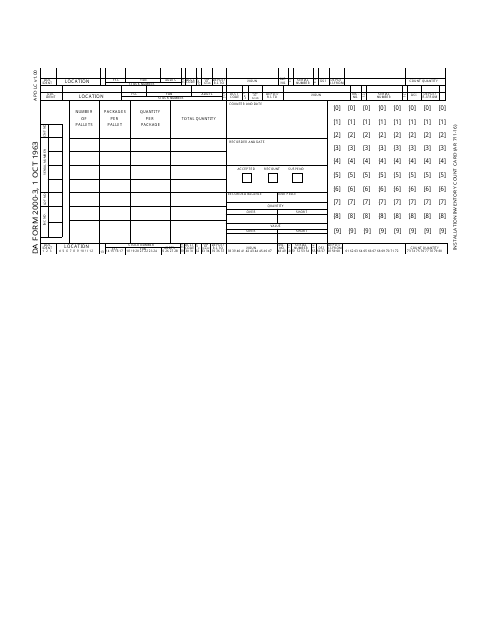

This type of document, the DA Form 2000-3 Installation Inventory Count Card, is used for keeping track of inventory during installations.

This type of template can be used as a standard operating procedure that consists of keeping track of the stock an organization owns, counting it, and recording the collected data for future analysis and management.